With access to cheap gas feedstock, regional producers are boosting their capacity while rivals cut back.

Almost 40 years after Aluminium Bahrain (Alba) poured its first hot metal, the Middle East is becoming a significant global aluminium producer. According to MEED Insight’s latest report on the sector - Mena Aluminium 2009: The region’s rise as a global producer - the Middle East produced 2.6 million tonnes of primary aluminium in 2008, a 6.5 per cent share of the global market.

While North Africa currently has limited aluminium production capacity, the report estimates that by 2010, assuming all planned projects in the Middle East and North Africa (Mena) region are completed on time, Mena production capacity will reach 4.3 million tonnes a year (t/y).

This figure will rise to 10.8 million t/y by 2013-14, assuming all the expansion projects at existing smelters and new facilities beyond 2010 go ahead, giving the Mena region about 19 per cent of global production capacity.

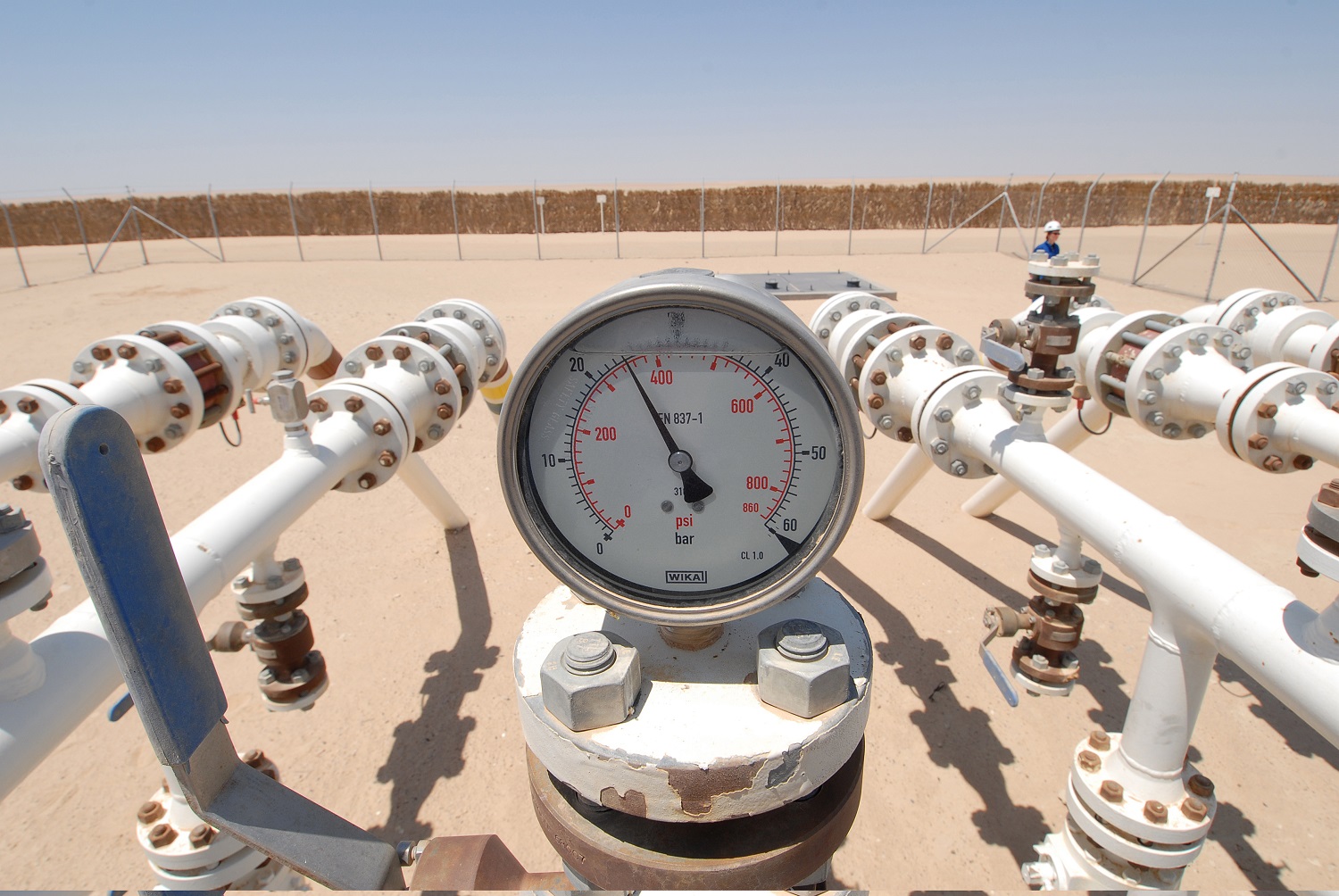

Feedstock advantage

State and private investors in the Middle East have been attracted to new aluminium smelters and capacity expansions because of the relatively low cost of producing the metal in the region. Having access to cheap gas feedstock gives Gulf regional producers an advantage over their rivals in Europe, for example, which have to import gas at market prices.

The first Gulf state-owned producers, such as Alba and Dubai Aluminium Company (Dubal), secured long-term gas feedstock contracts, which put them among the lowest-cost producers in the world. When the Alba smelter was built in 1971, a 20-year gas supply contract was agreed at $0.50 a million BTUs.

Recent entrants to the Middle East market have had to pay more, generally about $0.75-1.25 a million BTUs. Qatar Aluminium (Qatalum), for example, is believed to be paying $1 a million BTUs for gas feedstock for its facility at Mesaieed Industrial City. However, this compares well with global market prices of $3.90 a million BTUs for a futures contract traded on the New York Mercantile Exchange in 2009.

Even Gulf states without plentiful gas reserves benefit from the regional price advantage. Oman’s first smelter, at Sohar, was launched in 2005 by a joint venture of state-owned Oman Oil Company and Abu Dhabi Water & Electricity Authority (Adwea), with 40 per cent stakes, and Canadian mining giant Rio Tinto, which holds the remaining equity.

It reached its full production capacity of 360,000 t/y in February and has one of the lowest cost bases in the world, thanks in part to the low-cost Qatari gas feedstock made available via the Dolphin pipeline, combined with the use of new, efficient smelter technology.

Securing affordable long-term power supplies is also a major challenge for the region’s producers. Aluminium smelters compete for gas supplies with the petrochemicals and power industries, and it is up to producers to convince their respective governments of their case for receiving new allocations of gas.

There is also competition from major aluminium producers in China and Russia for bauxite, the raw material from which alumina is extracted before being refined into aluminium. Gulf producers will need to secure long-term and low-cost supplies of bauxite to ensure capacity expansions can go ahead, and to maintain their cost advantage.

Saudi Arabia does not yet have an aluminium smelter but has two in the planning stage and is the only country in the region with deposits of bauxite. Other states have had to seek supplies overseas. In May 2007, Dubal formed a joint venture to develop and operate the Sangaredi mine in Guinea, to secure its supplies of bauxite.

While sourcing feedstock and raw materials poses problems for the producers, so does the price of aluminium on the world markets. Over the past year, prices have collapsed, and if they do not recover, the case for investing in a new smelter or production line will be weakened.

In late May, aluminium on the London Metal Exchange was trading at $400 a tonne, compared with highs of $1,384 a tonne in July 2008, when prices peaked. The slump in price reflects the build-up of aluminium inventories and the drying up of demand due to low levels of construction and industrial activity.

Overseas demand is crucial for Middle East producers, because they export such a large proportion of their aluminium. While no Middle East producer has yet announced production cuts as a result of the slump in demand, the region’s smelters cannot operate indefinitely with prices at current levels.

Within the Mena region, GCC producers will continue to account for a major portion of aluminium production as a result of their planned expansions. Of the region’s 6.5 million tonnes of aluminium capacity planned beyond 2010, 4.4 million tonnes will be built in the GCC.

In the longer term, MEED Insight’s report estimates that by 2020, the GCC alone will produce about 10 million t/y of aluminium. In the Middle East as a whole, MEED Insight estimates that primary aluminium production is projected to grow at a compound annual growth rate of 14 per cent, up to 2013.

Qatalum and the UAE’s second-largest aluminium producer, Emirates Aluminium (Emal), have facilities due to come on stream by the end of 2009 and mid-2010 respectively. Qatalum’s Mesaieed facility will produce 575,000 t/y in its first phase, while the first phase of Emal’s facility in Abu Dhabi will add 700,000 t/y. They are set to be followed by Saudi Arabian Mining Company (Maaden) opening its integrated project at Ras al-Zour, which will produce 720,000 t/y in its first phase, due on stream around 2012.

Regional demand

North Africa also has major aluminium ambitions. In January 2008, the UK’s Klesch & Company finalised an estimated $8bn joint venture agreement with the Libyan African Investment Portfolio for the construction of a 725,000-t/y smelter at an unknown location, to be completed by 2011. In Algeria, Emal announced plans in 2007 to build a 700,000-t/y smelter at Beni Saf, in a joint venture with national oil company Sonatrach.

A major hurdle to the further growth of the region’s aluminium industry is the current lack of local consumers. Middle East manufacturers and industry consume only 16 per cent of its domestically produced primary aluminium, with the remaining 84 per cent exported. The extrusion industry - manufacturing aluminium products from its primary form - accounts for almost 70 per cent of the aluminium demand within the Middle East. Some 90 per cent of this extruded material is allocated to the construction market.

Due to low demand for finished aluminium products, there are a limited number of rolling and casting producers in the region. If the Middle East is to have a sophisticated downstream market that can absorb a greater proportion of locally produced aluminium, more rolling and casting factories will need to be built.

Mena aluminium production is rising steadily, but it is still a small industry. China has the greatest share of aluminium producers in the world - about 40 per cent compared with the Mena region’s 6.5 per cent. But the region’s governments have plans for industrial expansion that will create a larger and more sophisticated downstream industry for locally produced aluminium, which could in turn fuel further expansion. The region’s cheap gas supplies also put it at a major advantage in terms of cost.

In the short term, however, many aluminium producers’ expansion plans will remain on hold until new gas supplies can be secured, and until global demand recovers.

Exclusive industry report out now

Mena Aluminium 2009: The region’s rise as a global producerThis latest research report from MEED Insight provides a country-by-country assessment of the prospects for the regional aluminium industry. To order a copy of this report, contact MEED Insight at:

Telephone: +971 (0) 4367 1302

Email: insight@meed.com

MEED Insight provides exclusive research ser-vices as well as reports on the key sectors of the regional economy. To find out how MEED Insight can fulfil your research and information needs, email insight@meed.com or call +971 (0) 4367 1302.

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time to revise MGS package bids

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.