| By Jeffery Lau, business development and operations director at Aerodyne Middle East |

Aerodyne, a global drone-based end-to-end managed solutions provider, has completed more than 45,000 total drone flight operations and inspected more than 201,500 critical assets and major projects with a gross development value of $80bn.

Aerodyne’s core competencies lie in the use of autonomous artificial intelligence-driven drones that can perform critical assets inspection, geospatial and aerial mapping surveys, security and surveillance and progress monitoring.

One particular project that Aerodyne is working on is Petronas’ refinery and petrochemical integrated development (Rapid), the largest refinery and petrochemical complex in Southeast Asia. The $27bn project has a construction area of 2,000 hectares and will produce 9 million tonnes (MT) of petroleum products and 4.5MT of petrochemicals a year. Aerodyne is involved in aerial monitoring and reporting of the project progress.

Some of the issues that Aerodyne is addressing in this project include health, safety and environment, costly delays and mistakes from development and planning for project management and corporate communication.

Turnkey solution

Compared to traditional methods, drones can provide automation to accelerate the data acquisition process, with additional speed and accuracy during routine risky industrial inspections.

Drones can be equipped with a multitude of payload and sensors, depending on mission requirements or intended purposes. High-quality and complex inspection data can be obtained from critical and operational assets with the use of visual, thermal and Lidar sensors, among others, and further analysed and optimised to deliver data intelligence and prescriptive data to its stakeholders.

An on-site team of 30 engineers provides progress monitoring services on a 24/7 basis for Rapid. Through myPRISM, Aerodyne’s project reporting and surveillance solution, Aerodyne provides all stakeholders access to an enterprise collaboration dashboard for accurate progress reporting and monitoring. This greatly improves the project situational awareness to promote compliance and elimination of costly delays and mistakes, where stakeholders will always be aware of the project status.

An on-site team of 30 engineers provides progress monitoring services on a 24/7 basis for Rapid. Through myPRISM, Aerodyne’s project reporting and surveillance solution, Aerodyne provides all stakeholders access to an enterprise collaboration dashboard for accurate progress reporting and monitoring. This greatly improves the project situational awareness to promote compliance and elimination of costly delays and mistakes, where stakeholders will always be aware of the project status.

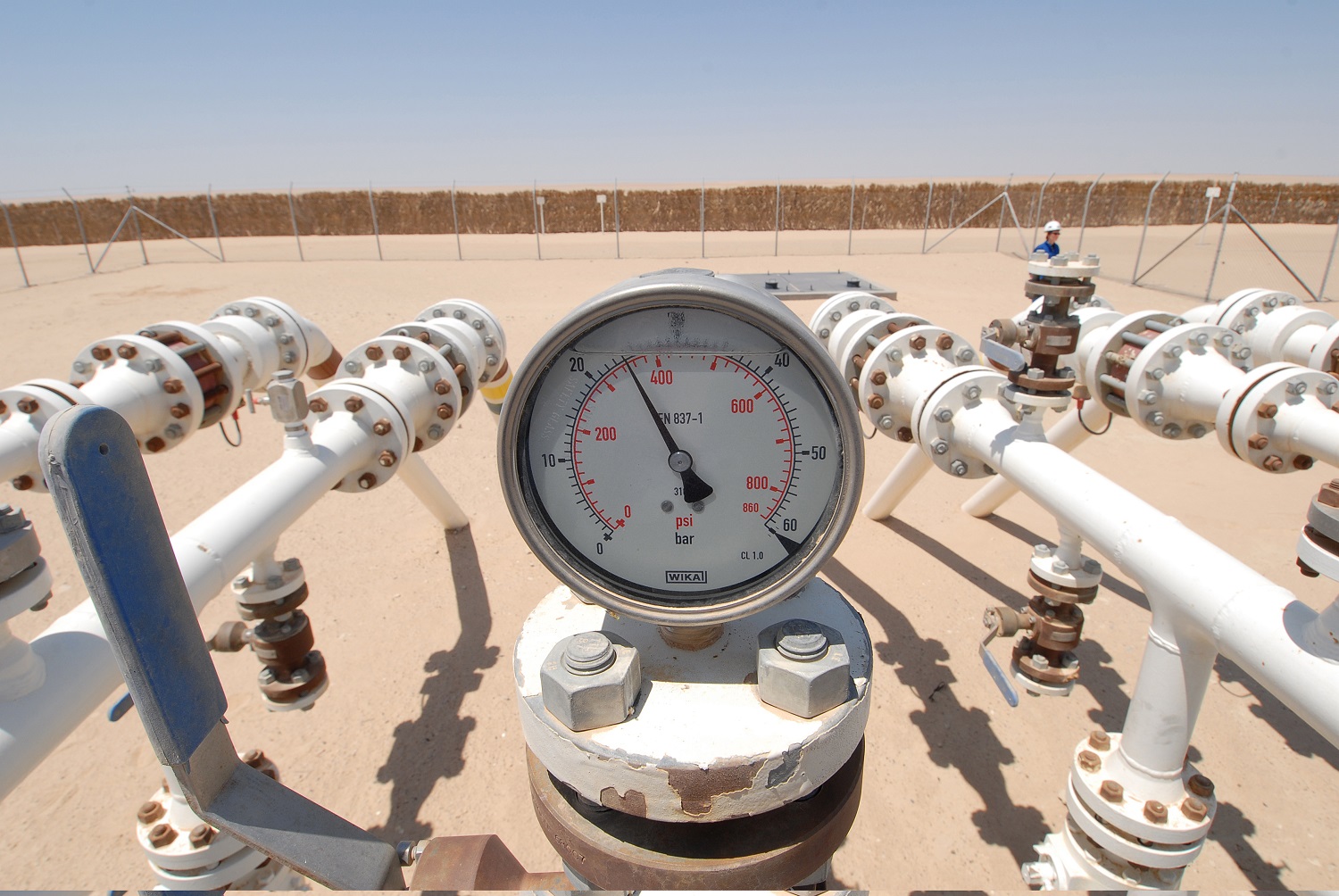

Drones can also provide pre-construction surveys by capturing images and data of a section of land. For aerial exploration, for instance, drones produce vital topographical information and accurate surveys of the targeted area. Oil and gas companies use this data to enable better planning and development of the potential areas, as well as to analyse the perfect spot to install the facilities. Drones record images to allow engineers to determine the right area to start building temporary passageways for facilities.

It is a common practice for facility owners to shut down their operations temporarily, especially for inspection. This usually causes companies to lose revenue during the shutdown. However, with drones, onshore and offshore vent stacks and exhausts can be inspected while they are live and not rely on scaffolding or cranes to enable technicians to complete the work efficiently and economically. Through efficient pinpointing of problem areas and improved ability to locate faults, drones enable companies to focus on the areas that need maintenance.

Upward progress

Captured visual data from the drones is used for better visualisation of assets. The 2D orthomosaic data is survey grade and can be extracted and combined with any computer-aided design (CAD) files. Many clients require 3D accurate reality models too. Imagine it like a digital copy of assets rather than in papers like the traditional way. The clients will have live data in the computer for enhanced collaboration and a digital record of the process.

Drones can be anywhere at the same time and provide real-time monitoring, resulting in the elevation of onsite security and safety. The application of drones in this field has already mitigated safety risks by removing the need for technicians to inspect the assets manually.

|

The real disruption comes from making sense of the data while removing human risk. Using the available data, Aerodyne is able to perform health analysis, comparing previous inspections to newer ones to give situational awareness of the components’ health. This allows for prioritised maintenance and mitigation plans to be put in place to achieve seamless process optimisation and asset management across the lifecycle of the project.

Drone utilisation and analytics will continue to be integrated into workflows of multiple industries, together with other technologies such as enterprise cloud applications, 5G/LTE connectivity, robotics, artificial intelligence and 3D printing. Virtual reality technology has the potential to change the entire industry by offering access to pre-construction surveys and virtual project site tours.

Overall, Aerodyne’s clients benefit from the improved project management and situational awareness, geospatial intelligence and optimised management of critical assets. There is a significant improvement in reporting time and a reduction in inspection turnaround time, resulting from faster data collation and report generation.

This article is extracted from a report produced by MEED and Mashreq titled Disrupting Oil & Gas. Click here to download the report

This article is extracted from a report produced by MEED and Mashreq titled Disrupting Oil & Gas. Click here to download the report

To know more about the MEED Mashreq Partnership, get in touch with us at MEEDMashreqPartnership@meed.com or find more info on www.meedmashreqconstructionhub.com

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time to revise MGS package bids

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.