Prequalification documents for the Al-Zour petrochemicals complex have been issued to prospective bidders, according to industry sources.

Kuwait Integrated Petroleum Industries Company (KIPIC), the project client, has already announced that companies have until 20 September to submit prequalification bids for the main engineering, procurement and construction (EPC) contracts.

The prequalification documents have revealed that KIPIC will divide the prequalification into two separate processes. One will be for the olefins, aromatics, and gasoline process units. The other will be for the marine work and pipelines.

The value and scope of the final EPC contracts is still yet to be finalised as the front-end engineering and design (feed) work is still being completed.

“Contractors are still expecting that there will be changes to the final design,” said one source.

The UK’s Wood Group is carrying out the front-end engineering and design (feed) work for the project.

At the moment, it is understood that the plan is to split the project up into three EPC packages:

- Aromatics 2 and the gasoline unit

- Olefins 3

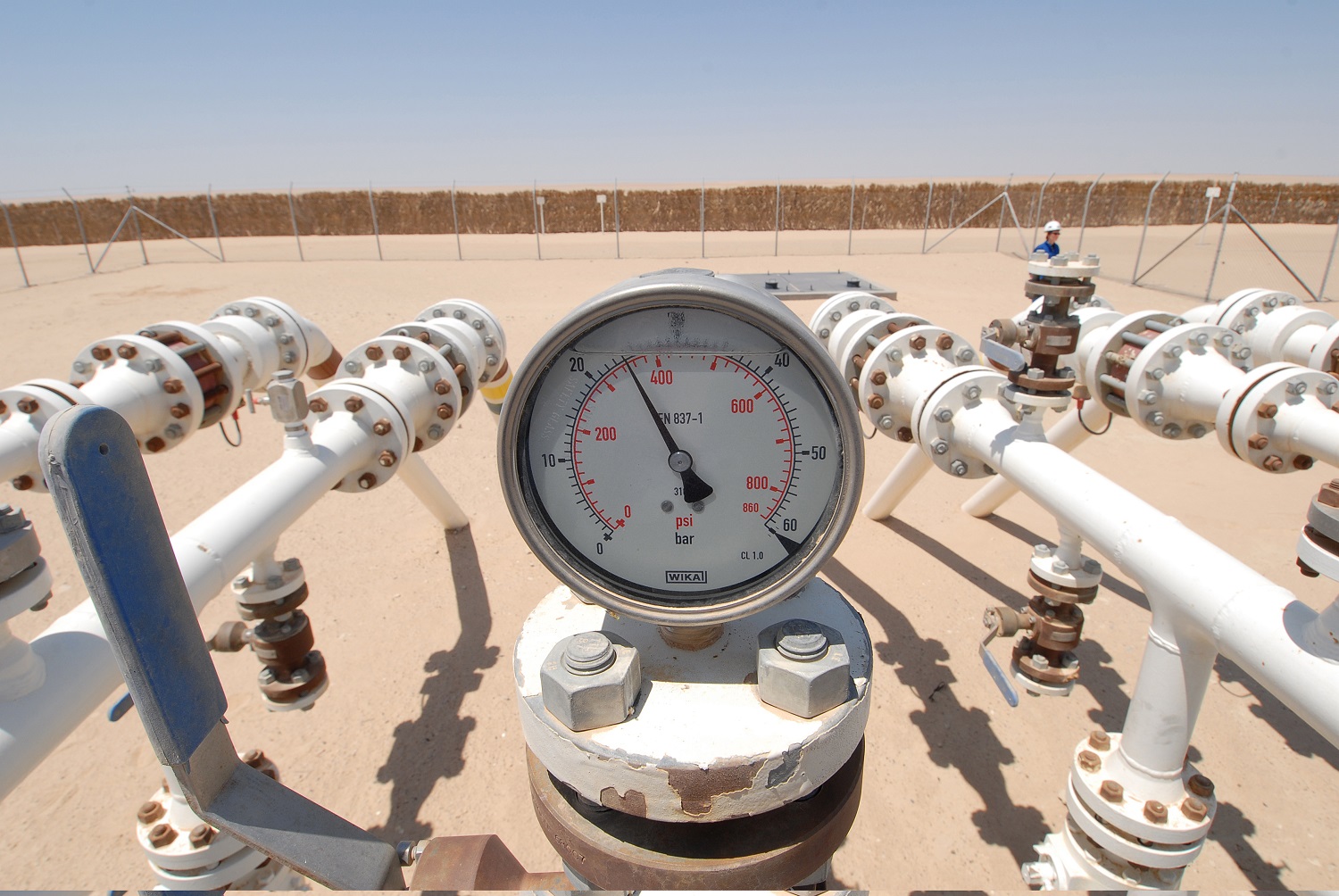

- Marine and pipelines

The olefins 3 block has been provisionally estimated to be worth $1.5bn, and the aromatics 2 plant has been valued at $5bn. The gasoline block has been estimated to be worth $1.3bn. These are provisional estimates and may change as the final scope of each unit has not been finalised.

Honeywell UOP was announced as the technology provider for the project in November.

The petrochemicals facility will be integrated with the $17bn Al-Zour New Refinery Project. When completed, it will be the largest integrated refinery and petrochemicals plant in Kuwait.

It will produce aromatics and propylene and is a key part of Kuwait’s broader industrial strategy.

The petrochemicals project includes a 50,000 barrel-a-day (b/d) residue fluid catalytic cracking (RFCC) complex with ethylene and propylene recovery, a 24,000 b/d gasoline desulphurisation unit and two units to treat propane for propylene production.

It will be capable of converting butane to isobutane and producing clean-fuels blending components including methyl tert-butyl ether (MTBE).

The facility will include a 66,000 b/d continuous catalyst regeneration (CCR) platforming unit with a 74,000 b/d naphtha hydrotreater to make gasoline blend stock.

The aromatics complex will have the capacity to make 1.4 million tonnes of paraxylene a year. A propane dehydrogenation unit will produce 660,000 tonnes a year of polymer-grade propylene.

Feed work for the planned petrochemicals plant was initially expected to be completed at the end of June 2018, but has been delayed.

The main EPC contracts for the new refinery project were awarded in mid-2015 and are under execution.

On 16 December, KIPIC denied MEED reports that the refinery project was delayed. It said work was proceeding on schedule and the refinery would start operations in May 2019.

In April, Khaled Mahdi, secretary general of Kuwait’s Supreme Council for Planning & Development, said the project had been delayed and is now targeting completion by December 2019.

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time to revise MGS package bids

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.