With its industrial ambitions at stake, Muscat is weighing up gas supply options

Strategy

Oman has been encouraging the development of non-hydrocarbon industries over the past decade as a way to decrease the economys reliance on crude revenues and to create jobs for nationals.

The governments diversification strategy is enshrined in its Vision 2020 document, which was penned in the mid-1990s when crude prices were under $10 a barrel.

One of the main targets in the plan is reducing the contribution of the oil sector to 9 per cent of GDP by 2020 and raising the contribution of manufacturing to 10 per cent by financing infrastructure and industrial projects. By 2011, oil revenues still accounted for about 35 per cent of GDP, but the countrys metals, mining and cement sectors have significantly expanded since the strategy was launched, especially around the northern port of Sohar.

With a population of almost 3 million, Oman does not have a large domestic demand for metals and minerals products. However, its location means it is a competitive supplier for markets in the Middle East and North Africa, Asia and Europe.

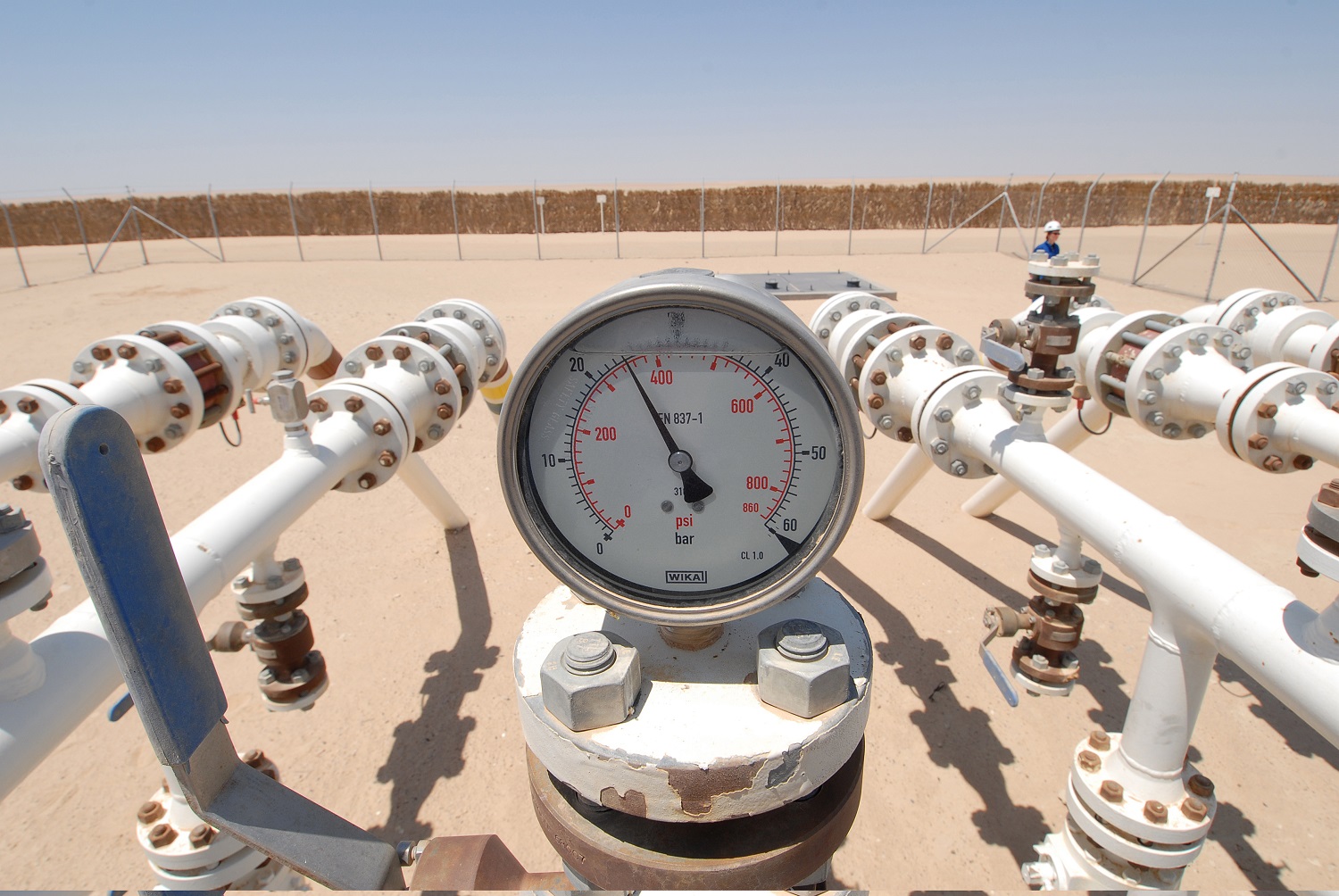

Until now, industries have benefited from an ample supply of low-priced gas to fuel operations, but future projects will find it more challenging to receive gas allocations.

Sub-sectors

Omans largest industrial project executed to date is the Sohar aluminium smelter, completed in 2008 by a joint venture of Oman Oil Company (40 per cent), Abu Dhabi Energy Company (Taqa 40 per cent) and Canadas Rio Tinto Alcan (20 per cent).

The 360,000 tonne-a-year (t/y) facility has provided the raw materials for the sultanate to develop a downstream aluminium industry. The largest of these projects, the $385m Sohar rolling mill, was completed by the local Takamul Investment Company at the end of 2013.

The bulk of Omans steel industry is run by Indias Jindal Shadeed Iron & Steel, which operates a 1.5 million-t/y direct reduced iron plant in Sohar. In April 2014, the company completed a melt shop with the capacity to produce 2 million t/y of semi-finished long products.

The country also has a growing iron ore pelletising sector, with Brazilian mining and metals giant Vale completing its $1.35bn plant in early 2012, with a capacity of 9 million t/y. Vale is considering doubling this capacity, while Jindal is also planning to build an iron ore pelletising plant at Sohar.

Outlook

Omans industrial ambitions are being held back by its limited potential to supply gas to new projects. However, with the $16bn Khazzan gas development set to come onstream later this decade, the sultanate could have more options. There is also the potential of gas imports from Iran after an agreement was signed between the two countries in early 2014.

One major project that has recently started construction is the local Sun Metals $400m steel project at Sur. But schemes announced several years ago, such as the gas-based steel plant in Sohar and the Dhofar steel facility in Salalah, remain in the early stages with no gas allocations.

The biggest project in the pipeline is the estimated $2.4bn expansion of the Sohar aluminium refinery, but the project is still in the initial stages due to a lack of gas.

One of the fastest-growing sectors in Oman is ferrochrome production, which utilises the sultanates reserves of chromite.

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time to revise MGS package bids

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.