Primary aluminium production in the region is now behind only China and the US

Aluminium has been at the heart of the GCCs industrial diversification agenda since 1971 when Manama commissioned the 120,000 tonnes a year (t/y) Aluminium Bahrain (Alba) smelter.

Benefitting from extremely low fuel costs, Manama, along with the regions other aluminium producers, recognised that they had an opportunity to attract investment and create jobs in aluminium production, which requires very high levels of energy.

Over the subsequent four decades, Alba smelter has undergone several major expansions and is today one of the biggest and most modern smelters in the world, operating five potlines with a combuned production capacity of 912,000 t/y, and employing nearly 3,000 people, of which 87 per cent are Bahraini.

In parallel with the Alba project, Dubai, Abu Dhabi, Qatar and Saudi Arabia have each invested heavily in aluminium production and in In the 12 months up to June 2014, the combined aluminium production from GCC smelters totalled 4.3 million tonnes.

Emerging powerhouse

Global aluminium production over the same period was between 47 million - 52 million tonnes according to the UK-headquartered International Aluminium Institute, meaning that the GCC now accounts for about 9 per cent of global output.

The GCC now outproduces every other region of world apart from China and the US.

The GCCs share of global production is up sharply from the 6.5 per cent share recorded in 2008, when GCC capacity stood at 2.6 million t/y, and is fast closing in on the 2020 target of 12 per cent set by the Gulf Aluminium Council (GAC) in 2010.

But achieving its goal will see the regions aluminium producers adopt a new approach that will redefine the sector for both the manufacturers and their suppliers.

After a decade of heavy capital investment and high growth, aluminium smelter projects in the region in the coming years will be focussed on expanding existing facilities rather than the devlopment of new greenfield schemes.

UAE

Abu Dhabi has been at the forefront of the most recent expansion, witnessing raw aluminium production rising from zero to 1.3 million t/y in the last six years after the successful commissioning of both phases of its Emirates Aluminium (Emal) smelter project.

Emal, a joint venture between Dubai Aluminium (Dubal), Abu Dhabis Mubadala and the Investment Corporation of Dubai (ICD), will produce a total of 1.3 million t/y of primary metal by the end of 2014. A recent $4.5bn expansion scheme has made Emal the largest single-site producer in the world, employing more than 3,000 people.

With more than 2 million t/y of capacity, the UAE now accounts for about 5 per cent of global supply

Emal is one of Abu Dhabis greatest diversification success stories and a large part of the credit must go to Dubal, who is the technical partner of the scheme. Dubal itself operates the GCCs second-oldest smelter, established in 1979, located a few kilometres north in the Jebel Ali Freezone and which has a capacity of more than 1 million t/y of primary metal.

After a merger in 2013, both smelters are now owned by Mubadala and the ICD and operated by Emirates Global Aluminium (EGA). With more than 2 million t/y of capacity, the UAE now accounts for about 5 per cent of global supply. The vast majority of this raw metal is exported into foreign markets, where it is converted into end-user products for manufacturing, construction and consumer markets.

Saudi Arabia

This export-led strategy is in marked contrast to Saudi Arabia, where a new world-scale smelter is currently commissioning in the Eastern Province. The 740,000-t/y facility is being built by Saudi Arabian Mining Company (Maaden) and the US Alcoa at Ras al-Khair and is aimed at both the domestic and export markets.

Riyadh has prioritised industrial diversification as a means to increase job creation, especially in more remote areas, and aluminium production is set to be a key sector in this aim.

The kingdom is the only country in the GCC that has its own bauxite reserves at Al-Baitha in the north. When completed, 4 million t/y of bauxite from the mine will be transported by rail to the processing facilities in Ras al-Khair.

A 1.8 million-t/y alumina refinery will process the bauxite, which in turn will feed the smelter. Primary metal will then be utilised by several downstream converters in Ras al-Khair, including a 380,000-t/y rolling mill and potential automotive production.

Setting up conversion industries around a smelter is not a new concept in the GCC and there is already a precedent for how it can be implemented successfully at the regions oldest smelter operation.

Bahrain

State-owned Alba started producing primary aluminium in 1971, with an original capacity of 120,000 t/y. The smelter was constructed in order to both diversify the Bahraini economy as well as provide skilled jobs for locals.

Today, the smelter has undergone several expansions and modernisation programmes and capacity stands at just over 900,000 t/y, with 87 per cent of the workforce being Bahraini.

About 50 per cent of the Alba offtake is fed into an aluminium downstream cluster that sits adjacent to the facility. Industries include a wire rod mill, an extrusion plant and a rolling mill. The importance of Alba and its surrounding downstream conversion plants to Bahrain is such that it now contributes about 10 per cent of the countrys GDP.

A further expansion has long been mooted at Alba that would see a sixth potline added as well as major debottlenecking work that would push the capacity of the plant to about 1.3 million t/y.

After three years of uncertainty and stagnation in Bahrains project market, the scheme is now moving again. MEED reported in July that a gas allocation had been awarded to Alba that would enable it to push ahead with the potline expansion. However, with a budget that is expected to be in excess of $2bn, the project still has some way to go before it gets to the construction tendering phase.

After three years of uncertainty and stagnation in Bahrains project market, the Alba refinery scheme is now moving again

Oman

Sohar Aluminium in Oman has been producing 375,000 t/y of raw metal since it was commissioned in 2008. A joint venture between Oman Oil Company, Abu Dhabi National Energy Company and Canadas Rio Tinto Alcan, the smelter has no immediate plans for significant expansion. However, a productivity optimisation project is being implemented that will increase capacity by 28,000 t/y by 2019.

Qatar

Qatar Aluminium is a joint venture between Qatar Petroleum and Norways Norsk Hydro, and produces 585,000 t/y of primary aluminium from its complex at Mesaieed in the south of the country.

The smelter was fully commissioned in 2011 and is aimed squarely at the export market, with the vast majority of its offtake being sold into the North American market.

There has been occasional talk of an expansion over the last few years, but this looks unlikely in the short to mid-term, due to Dohas commitment to more pressing matters such as massive infrastructure expansion projects.

MENA region

Across the rest of the Mena region, Iran runs four modest smelters with a combined capacity of 457,000 t/y, with no plans for further expansion. Egypt Aluminiums smelters capacity of 320,000 t/y has been lowered in recent years to 195,000 t/y.

There is scope for future expansion, but it is almost certain that the past decade will be regarded as the golden period for production in the GCC region.

The sixth potline at Alba is the only significant expansion that we expect in the Middle East in the next five years, says Marco Georgiou, head of aluminium primary and products at UK-based analyst CRU Group. We dont see significant regional expansion coming from anywhere else.

At present, the [aluminium] market has a large inventory to get rid of. After that there is definite scope for new capacity to come on stream

Marco Georgiou, CRU Group

Bauxite is the worlds most abundant mineral and global aluminium growth is stable at 5-7 per cent a year, so there is scope for further expanding operations or even greenfield schemes as a means of diversification.

At present, the [aluminium] market has a large inventory to get rid of and this is going to take about five years to clear, says Georgiou. After that there is definite scope for new capacity to come on stream.

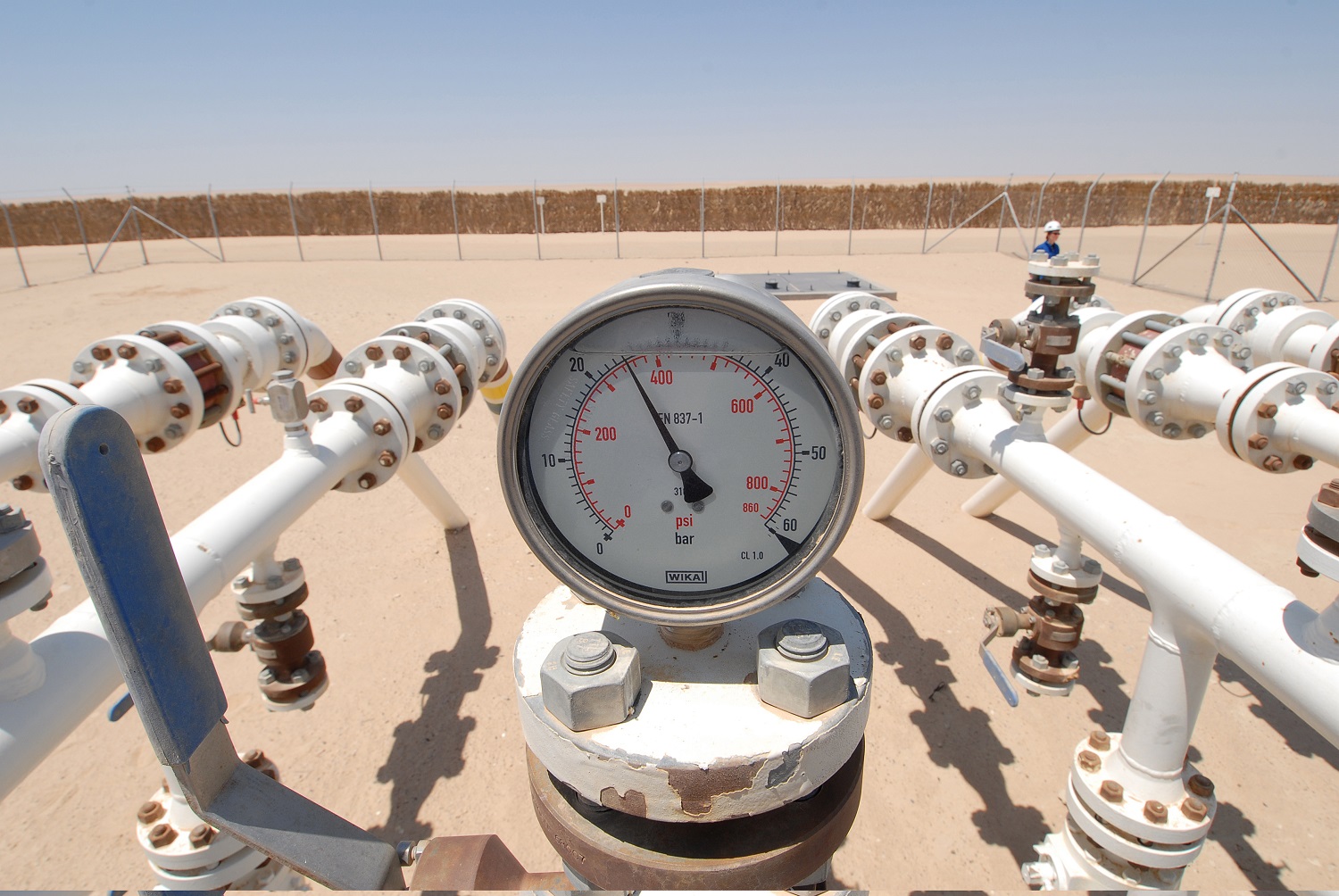

However, smelting aluminium is the most energy-intensive industrial process and any new scheme needs to be built at a world-scale level to justify the initial capital expenditure. The plant also needs a large power source, which usually means a significant gas or fuel allocation needs to be made.

These extremely high start-up costs combined with the need for a long-term fuel commitment discounts many Mena nations. Algeria was considering a smelter project in 2010-11, but this has stalled. Meanwhile, Libyas plans were on shaky ground even before they came to an abrupt halt with the civil war of 2011.

The recent golden age of new smelter operations in the GCC looks destined not to be emulated in the next few years unless there is a seismic change in the regions political and economic climate.

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time to revise MGS package bids

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.