Delays in completing pipeline will hit reputation of firms working in the region

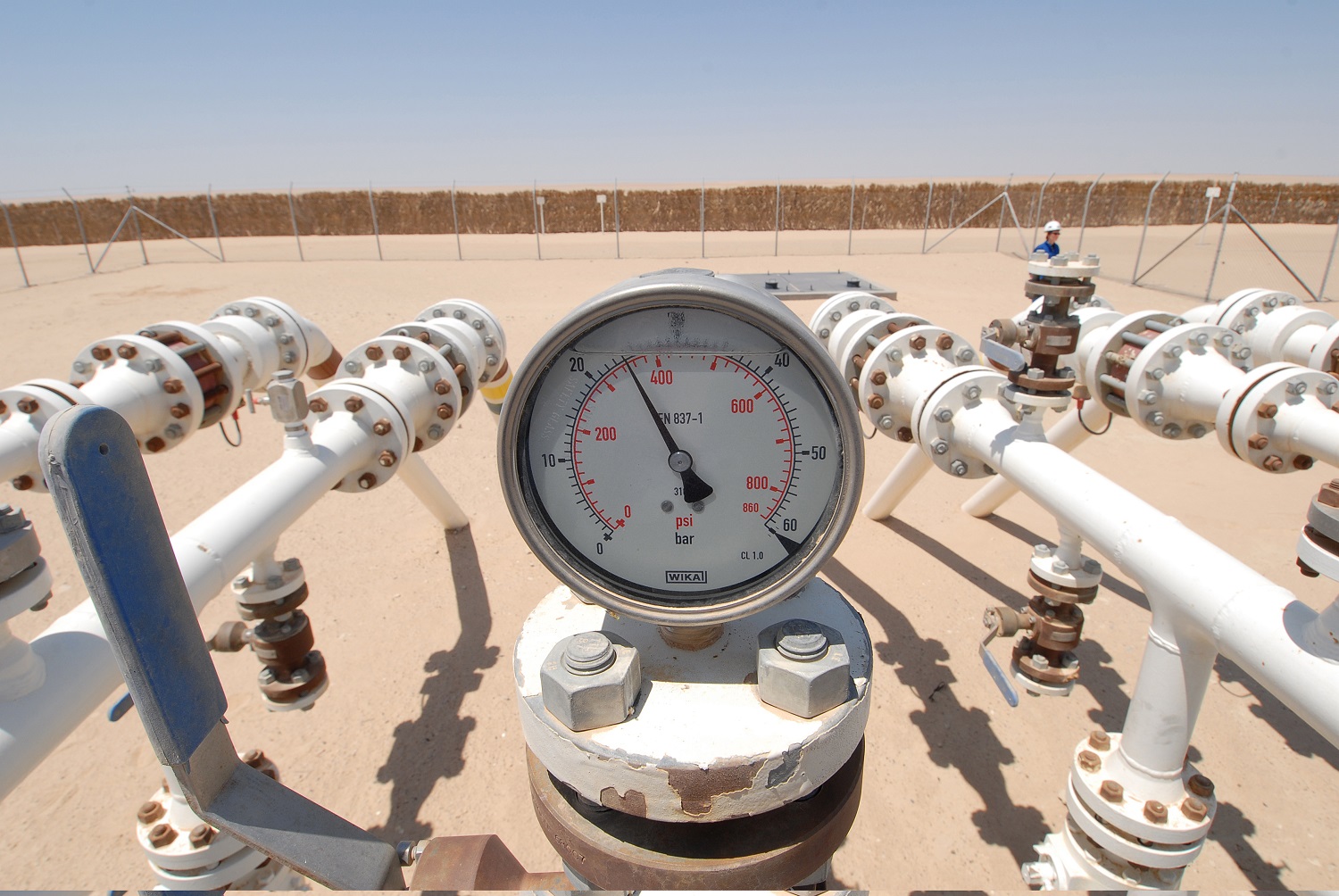

A pipeline intended to allow Abu Dhabi’s oil exports to bypass the Strait of Hormuz will not be operational for another five to six months, almost a year and a half after construction work was reported to have been completed. The delays could be a blow to the reputation of Chinese contractors in the region, say some sources.

The 1.8 million-barrel-a-day (b/d) pipeline is almost complete and could be operational by May or June, says UAE Oil Minister, Mohamed bin Dhaen al-Hamli, speaking to journalists on the sidelines of a conference in Abu Dhabi.

The 48-inch pipeline runs 370-kilometres from the Habshan oil fields in the southwest of Abu Dhabi to Fujairah, allowing almost half of the emirate’s crude oil exports to bypass the Strait of Hormuz, the narrow shipping lane between the Omani Musandam Peninsula and Iran through which around 20 per cent of the world’s traded oil passes. At the end of December, Iran threatened to close the strait in response to increased US sanctions against the regime, as a result of its pursuit of nuclear weapons capabililty.

Abu Dhabi-owned International Petroleum Investment Company (Ipic) awarded almost $3.3bn worth of engineering, procurement and construction (EPC) contracts in 2007 to two Chinese state-owned firms; China Petroleum Engineering & Construction Corporation and China Petroleum Pipeline Bureau.

The Chinese pair completed the bulk of construction in November 2010, already a year behind schedule due to material procurement problems. Testing was expected to take place before the end of the 2010. However, Australia’s WorleyParsons, who carried out the front-end engineering and design (feed), was subsequently drafted in to oversee an emergency recovery programme due to numerous technical problems blamed on the contractors.

The award of the contract to the Chinese firms was considered a test case for Chinese expertise in the regional oil and gas sector. Chinese hydrocarbons contracting in the GCC had never really recovered from problems with the gathering centre (GC) 27 and 28 contract awards in Kuwait in 1995 in the aftermath of the Iraqi invasion. The contract, undertaken by state-owned China National Petroleum Company, suffered massive delays with the GCs only commissioned in 2001.

“It is not uncommon that they fail, or that their equipment breaks relatively quickly, after which the runners-up are called in and expected to clean the mess up. But this happens at more-or-less the same price,” says one industry source.

According to figures from regional projects tracker MEED Projects, more than $196bn-worth of oil and gas EPC contracts have been awarded in the GCC since 2005. Of this only $4bn has been awarded to Chinese contractors, with $3.42bn from the UAE and $566m from Saudi Arabia. The Hormuz pipeline work makes up the majority of their work, dwarfing their contributions in refining ($140m) and oil and gas production ($130m).

The delays to the pipeline has been seen by one industry source as partly the result of the wider trend among Gulf clients to opt for the lowest bidder on all projects on principle, in an effort to keep a lid on cost inflation over the past two to three years. EPC costs rose dramatically in the run up to the pipeline’s construction with raw materials rising to record highs in 2008 and 2009. However, cost inflation may not have been the only motivation behind the choice of contractors.

The Hormuz pipeline’s cost, coming in at $3.3bn is well above the going rate for this type of pipeline and was originally budgeted at much lower. The deal was not awarded through a tendering process, but followed government-level negotiations between Beijing and Abu Dhabi.

“Saudi Arabia appears to be the exception to the rule here, preferring to use a greater proportion of Western companies and suffering less contractor malfunctions,” says the source.

Saudi Aramco has tended to use more experienced firms such as the US’ Fluor or France’s Technip to carry out the engineering, procurement, construction and management (EPCM, while allowing less experienced firms to carry out the construction under supervision. However, it is unclear if Saudi clients face cost overruns as a result.

Chinese contractors do have another opportunity to redeem their reputation. Over the past two years, China’s Shandong 3 Electric Power Construction Corporation (Sepco-3) has won the country’s first large-scale EPC power station contracts in the region for independent power plants at Ras al-Kheir (formerly Ras al-Zour) and Rabigh in Saudi Arabia, as well as Oman’s Salalah independent water and power plant. The EPC community will be watching how they perform on these schemes again (MEED 28:5:09).

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time for MGS package revised prices

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.