The domestic market is the prime focus of much of the states industry

Strategy

Egypt has a large and diversified industrial base, although its relatively poor manufactured export performance by Asian standards points to a failure to take full advantage of this.

Aside from the textiles and clothing industry, which is strongly export-oriented, the domestic market is the prime focus of much of the countrys industry, although many of the more ambitious companies such as Ghabbour Auto and El-Sewedy Electric Cables look to supplement their earnings through exports and foreign investments.

The development of Egypts industrial sector and the rise in manufactured exports was one of the notable achievements of Prime Minister Ahmed Nazifs government between 2004-10, when the then President Hosni Mubarak sought to promote a resurgence on the back of privatisation.

Under Mubarak, the nationalisation of the 1960s was reversed as the government embraced privatisation beginning in the 1990s. About half of the 314 state-owned enterprises were sold, either to strategic investors or, more commonly, through share flotations. Private ownership now prevails in most segments of Egyptian industry; the main exceptions are the sugar industry, in which state-owned firms account for about two-thirds of production, and aluminium and cigarettes, although the leading producers in these are minority-owned by private investors.

Between 2005 and 2010, Egypts manufactured exports doubled, but the industrial sector has struggled since Mubarak was removed in 2011. Domestic demand has fallen, labour militancy has increased, access to foreign exchange to finance imports of equipment and raw materials has become more difficult, and supplies of electricity and natural gas have frequently been cut off. Hundreds of factories have closed or reduced production.

Schemes set up by Mubaraks successor Mohamed Mursi and by the interim government formed after Mursis removal have had only limited success in channelling funds into struggling industries.

Some segments have coped well with the turbulent conditions since 2011, however, including food and white goods producers, the automotive sector, steel and ready-made garments. No international investors have exited and companies including South Koreas Samsung Electronics, Swedens Electrolux, Switzerlands Nestle and the US Coca Cola have all persevered with new projects or expansions of their production lines.

In May, the Egyptian Stock Exchange witnessed its first initial public offering (IPO) since 2010, for a stake in Arabian Cement Company. The IPO was heavily oversubscribed, despite well-publicised difficulties facing the cement sector.

Sub-sectors

One of the fastest-growing industrial sectors in recent years has been building materials, through private investments in greenfield schemes, or through privatisation. However, these developments have been tainted by political controversy, with criticism focusing on the high level of foreign ownership in the cement industry and on the dominance of firms controlled by Ahmed Ezz, a Mubarak stalwart facing corruption charges, in the steel industry.

In the mid 2000s, heavy investment in the cement sector saw production leap ahead of demand, leaving a huge surplus for export. Exports peaked at almost 7 million tonnes in 2006, then declined as local demand soared. Capacity reached 50 million tonnes in 2010 and was set to increase by more than 13 million tonnes over the next two years on the basis of new licences awarded and expansions planned. However, progress slowed amid political instability, the economic slowdown, high financing costs and the likelihood of hikes in fuel prices. Even so, many projects launched before the revolution came on stream, and by 2014, capacity was about 58 million tonnes.

The steel sector is concentrated around the Ezz Steel group, which accounts for almost half of all rebar production and most of the countrys flat product output. Ahmed Ezz, facing a retrial on corruption charges, has resigned as chairman and has no active corporate role in the firm.

Ezz Steel continues to function normally and reported profit after tax of £E134m ($19m) in 2013 on total sales of £E21.3bn. The firms total capacity is 5.8 million tonnes a year (t/y) of finished steel. In 2013, it produced 3.7 million tonnes of long products, almost entirely for the local market, and 990,000 tonnes of flat products, half of which was exported. Its total sales reached about $6bn.

The group faces competition from small operators, the most ambitious of which belong to Ahmed Abu Hashima, whose assets are held under the umbrella of Egyptian Steel, a holding company he set up in 2010 in partnership with Sheikh Mohammed bin Abdullah bin Jassim al-Thani, a cousin of the former emir of Qatar.

In the automotive sector, several ventures have started up since the mid-1980s, when the US General Motors set up a joint venture with Japans Isuzu to produce cars and pickup trucks. Until then, the only producer was state-owned El-Nasr Automotive Company (Nasco), which assembled Fiats from kits supplied by Zastava Automobili in the former Yugoslavia. The most successful new operation is Ghabbour Auto, which built on its experience of making buses and trucks to become a dominant player in the market, producing Hyundai cars.

The textiles sector is boosted by trade agreements, allowing it to export freely to the EU. Since Egypts peace treaty with Israel in 1979, companies that register in Qualifying Industrial Zones have tariff and quota-free access to the US market as long as the products have at least 10.5 per cent Israeli content.

The sector has been affected by the political turbulence and economic slowdown of the past three years. The cotton yarn industry is predominantly state-owned, and the big mills in the Delta region of Mehall al-Kubra have been the scene of persistent labour unrest both before and after the 2011 revolution. Labour relations have been strained in textile firms that have undergone privatisation.

Outlook

A shortage of natural gas to fire kilns means the cement industry is operating below full capacity and companies are investing to adapt their production processes to operate with coal and biomass, despite protests from the environmental lobby.

Arabian Cement Company, for example, has invested $35m in refitting production lines to run on 70 per cent coal and 30 per cent refuse-derived fuel once it receives its licence. A positive response to the firms IPO in May showed investors see potential in the countrys cement sector, but official targets for increasing capacity to 80 million tonnes by 2020 appear unrealistic.

There is also a threat of renationalisation in the sector. In September 2012, a local court ruled Asyut Cement, owned 95 per cent by Mexicos Cemex, should be renationalised, after workers demanded permanent contracts, bonus payments and improved working conditions. In September 2011, three other industrial firms were ordered back into state hands, but this has yet to take place. The post-Mursi government is seen as having a more investor-friendly policy, and it is likely those suits will come to nothing.

Steel producers have also struggled with rising costs of energy and raw materials, but will benefit from the expected increase in investment in housing and infrastructure. Abu Hashimas stated ambition is to raise his share of the Egyptian steel market from 7 per cent in 2012 to 20 per cent in 2017. In 2011-12, he acquired a steel wire rod plant in Alexandria via his Industrial Investment Company (ICC), and the facility was refurbished over the next two years.

ICC also secured a licence for £E70m to build a large steel complex in Beni Suef, to the south of Cairo, which has benefited from the southern extension of the national gas grid. Another Egyptian Steel subsidiary, National Port Said Steel Company, secured a licence to build a plant in Ain el-Sokhna, at the southern entrance to the Suez Canal.

The imminent start-up of the refurbished Alexandria plant will push Egyptian Steels total output capacity to about 550,000 t/y, and once Beni Suef and Ain el-Sokhna come on stream over the next two years, the company will be able to produce close to 2 million t/y in total. Abu Hashima has engaged Italys Danieli to build all of his plants. Danieli was also responsible for most of Ezz Steels projects.

Abu Hashima has said he plans to launch an IPO for Egyptian Steel next year.

Meanwhile, Ghabbour Auto is looking beyond the domestic market. The firm has a strong presence in Iraq and is extending into Libya and Algeria. It opened a line producing Chinese Geely passenger cars in 2012, and is planning to launch a new Hyundai line. Sales of Geelys reached almost 10,000 in Egypt in 2013.

Foreign investors have a strong presence in most sectors of Egyptian industry, including pharmaceuticals, where major players include the UKs GlaxoSmithKline and the US Eli Lilly, Pfizer and Bristol Myers Squibb.

One of the most scrutinised investment deals during the revolution was a takeover of the local Olympic Groups consumer durables business by Electrolux. It was reappraised in light of changed circumstances and the sale was finally effected in September 2011 for about $400m, securing Electrolux a 30 per cent share of the Egyptian market for washing machines, refrigerators and cookers.

South Koreas Samsung Electronics too, as Samsung Electronics Benelux, manufactures appliances for export, largely to Europe. Phase one of its projects involved a $240m production line for LED and LCD television screens and computer monitors, and started up in 2013.

Samsung recently embarked on a $60m expansion, targeting annual production of 8 million screens by 2017. The company has set up a research and development centre in Beni Suef, and is studying plans for three more production phases involving fridges, air conditioners and washing machines.

Nestle and Coca Cola have also announced plans for further investment in their existing facilities.

You might also like...

Ajban financial close expected by third quarter

23 April 2024

TotalEnergies awards Marsa LNG contracts

23 April 2024

Neom tenders Oxagon health centre contract

23 April 2024

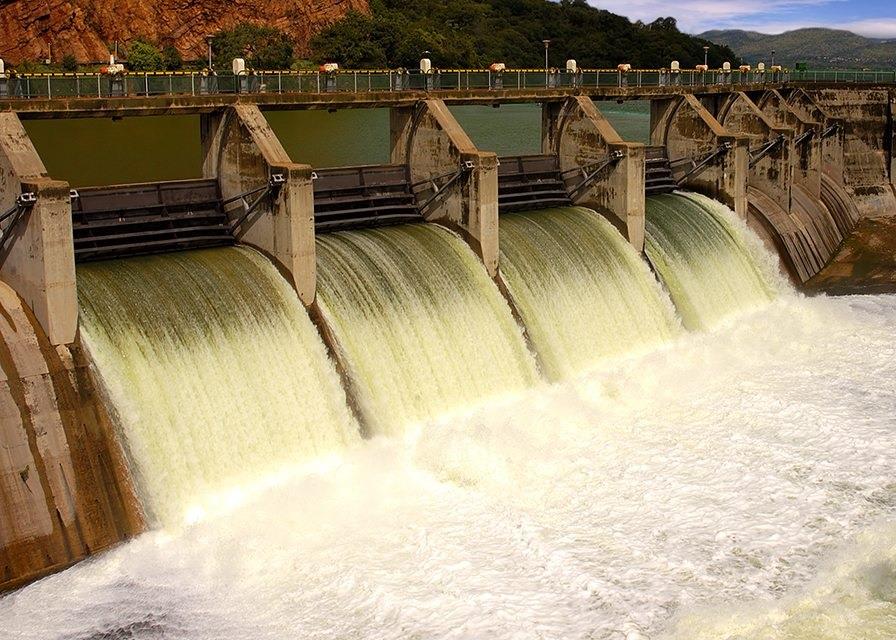

Neom hydro project moves to prequalification

23 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.