JAPANESE engineering firms are proving their staying power in the fiercely competitive Middle East market. By adapting their working practices they have been able to retain their market share despite a strong yen and the emergence of new competitors from China and Korea.

Japanese firms reacted swiftly to limit the impact of the strong yen by shifting much of their production to other Asian countries to reduce costs. Last year that process was accelerated when the exchange rate dipped below $1=Y100. At Mitsui Engineering & Shipbuilding (MES), only about 10-15 per cent of a quote for Middle East contracts is calculated in yen. 'We now outsource to other countries,' says Shinsuke Nippo, Deputy Manager of International Sales. 'The more complex engineering work is still done here in Tokyo, but the more mundane design work in now done in India, the Philippines and Thailand.'

This trend is mirrored at other Japanese engineering firms. 'Competition is getting very tough and we are having to change,' says Yazuro Daido, a vice-president at Chiyoda Corporation. The company has engineering offices in the Philippines, Malaysia and Singapore, and a joint venture in India. 'Most work is still done at our Yokohama office, but this will change,' Daido adds.

Japan's engineering giants still look to the Middle East for a sizeable proportion of their overseas business. The region is expected to account for 20-30 per cent of Mitsubishi Heavy Industries (MHI) exports this year, largely on the back of the lump sum turnkey contract to build the 2,400- MW Ghazlan-2 power plant in Saudi Arabia. The contract, which is worth $1,500 million, was awarded in September and involves the procurement and installation of four steam turbine generators with a capacity of 600- MW each, and all auxiliary facilities.

Of all the Japanese engineering giants, Chiyoda Corporation has proved to be one of the most successful. In what has been a difficult period for the company as a whole, the Middle East has been its saving grace. In the last 12 months alone it has won contracts totalling almost $1,000 million.

'The Middle East has been contributing a great deal to the turnover of the company over the past two or three years,' says Daido. About 65 per cent of Chiyoda's revenue comes from its overseas markets. Of this, 50- 60 per cent derives from the Middle East.

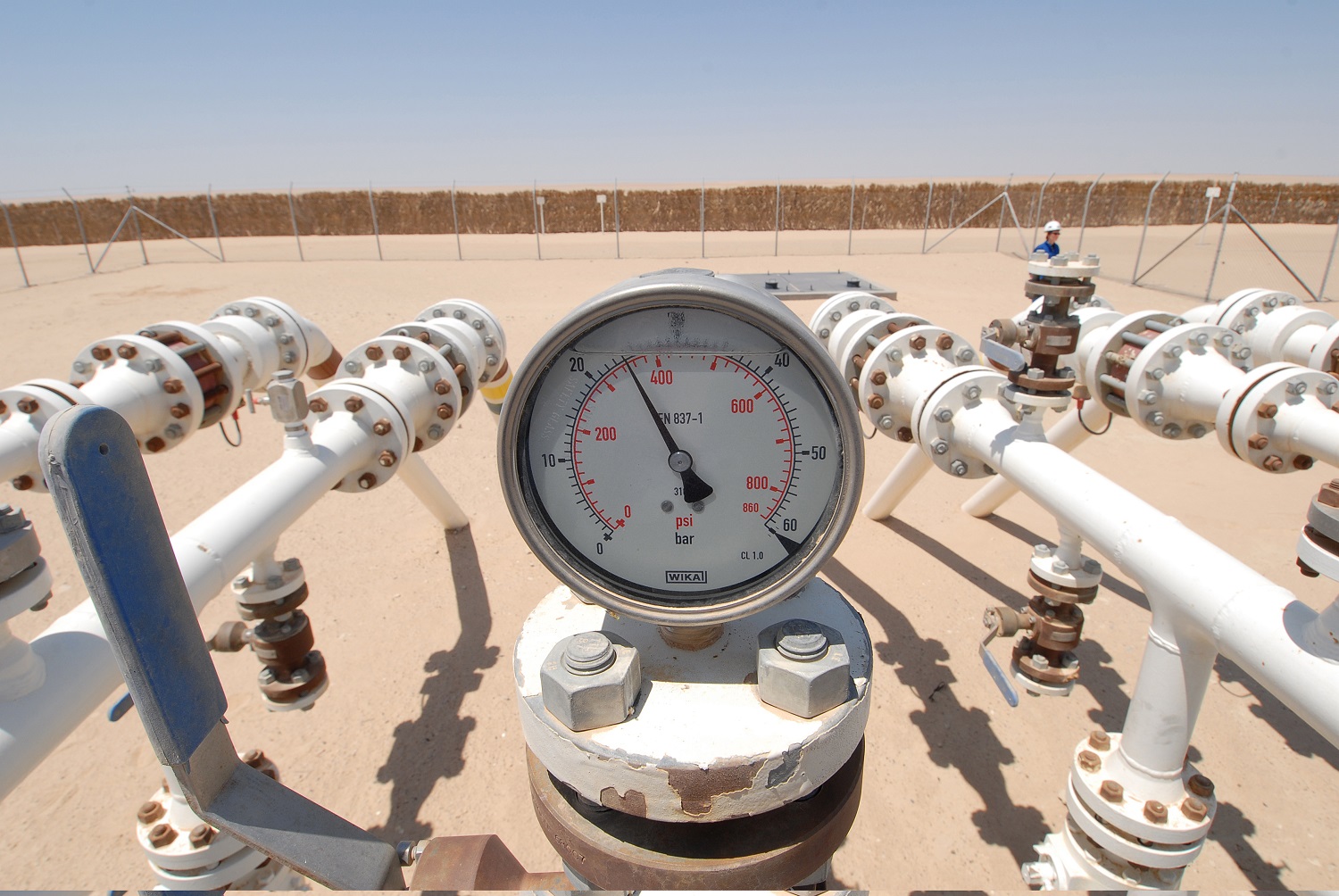

Qatar has become one of Chiyoda's most active markets in recent years. In 1994, the company was awarded the engineering, procurement and construction (EPC) contract, worth in excess of $2,000 million, to build the three liquefied natural gas (LNG) trains for Qatargas. The trains, each with a capacity of 2 million tonnes a year (t/y), are the centrepiece of the new Ras Laffan industrial city. Work has kept to schedule, with the first gas train commissioned in November and the second in December; the third train will be commissioned in late 1998. The first shipment of LNG is due to arrive in Japan in January.

Big in Qatar

More work has come out of Qatar this year. In November, the company signed a $410 million contract for the lump sum turnkey construction of a new plant for Qatar Fuel Additives Company (Qafac). The plant will have a capacity of 610,000 t/y of methyl tertiary butyl ether (MTBE) and 825,000 t/y of methanol. Qafac has a 50 per cent stake in the project. The other partners are Taiwan's China Petroleum Corporation, Canada's International Octane and Taiwan's Lee Chang Yung Chemical Industrial Corporation.

Qatar has certainly served Chiyoda well, but the company has also found success elsewhere in the Gulf. In mid-November, a joint venture of Chiyoda and the UK's Foster Wheeler signed a contract with Oman LNG for the construction of the Al-Ghalilah liquefaction plant with a capacity of 6.6 million t/y. The total cost of the plant has been estimated at $2,250 million, with the first train due for completion in 38 months and the second in 48 months.

Firm oil prices have left Japanese firms optimistic that some of the extra revenues will go towards new infrastructure and hydrocarbons projects. There is also confidence that they will be able to see off competition from Korean and Chinese companies, which are eagerly trying to expand their market share in the Middle East. 'Competition with South Korean companies is very fierce in Asian markets where price is the most important factor,' says Mitsui's Nippo. 'But in the Middle East there is more emphasis on experience and quality.'

MHI is looking carefully at moves towards the private financing of infrastructure. Pakistan and Turkey have taken the lead in independent power projects (IPPs), and even Saudi Arabia is also taking its first tentative steps towards private power development. MHI believes there are substantial obstacles to the development of IPPs in Saudi Arabia, notably in pricing and the creation of suitable Islamic financing mechanisms. The company has no plans to take equity stakes in IPPs, and is planning to remain solely an EPC contractor.

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time for MGS package revised prices

18 April 2024

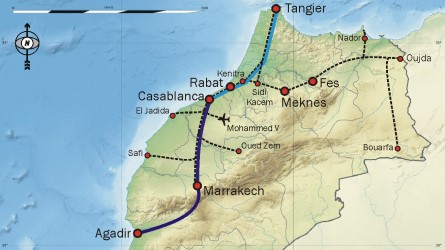

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.