When Saudi Aramco rewrote a major contract just months after awarding it to US offshore specialist J Ray McDermott in August 2007, it revealed a change in corporate strategy. By handing 20 per cent of the contract to Italy’s Saipem and local firms Taqa and Al-Rushaid, it demonstrated that the promotion of local content would figure prominently in future contract awards.

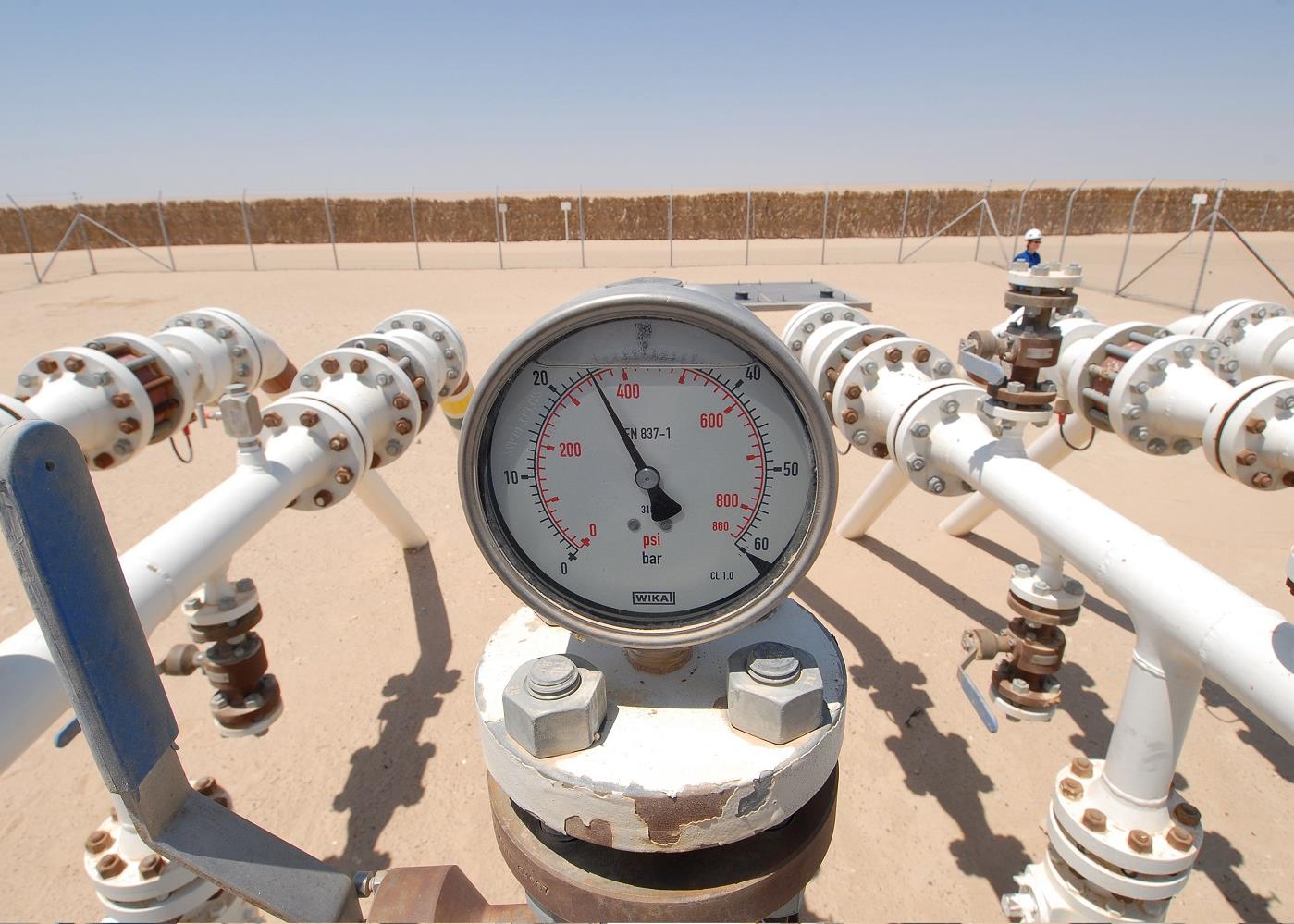

Boosting local content is a critical component of Aramco’s $40bn materials procurement programme for the 2007-11 period. As the company attempts to realise its 12.5 million barrel a day production capacity increase by 2011, it has an expanding shopping list of material needs: static equipment, such as pipes, pipefitting, valves and vessels worth $16bn; drilling and chemical equipment worth $11.6bn; and machinery worth $3.76bn.

Purchasing materials

Aramco’s strategy reflects the tight contracting market. Because of the global competition for all forms of materials, orders for major project items requiring long lead times are placed before an engineering, procurement and construction contract is awarded. The purchasing of other materials, however, is generally left to the project contractors, once standards and specifications have been determined.

Esam Mousli, vice-president of materials supply at Aramco, says nearly 50 per cent of its materials and equipment purchases are potential targets for local manufacturers, with 20 per cent already made in Saudi Arabia. Materials include pipes, valves, chemicals and wellheads.

Mousli says the company’s success in addressing hikes in demand for materials results from adopting an integrated approach to the supply chain. This strategy encompasses manufacturers, vendors, service providers, customers and stakeholders. If Aramco’s materials supply division is to ensure that the company continues to obtain the materials it needs in an effective manner, says Mousli, it must develop and implement strategies that shift the traditional focus on price to a system based on value.

Manufacturing support

“Saudi Aramco is a strong supporter of the local manufacturing industry and attempts to maximise the local content of its projects to the fullest extent possible,” says Sadad al-Husseini, former executive vice-president of exploration and production at Aramco.

But there are limits to the company’s capacity to support local industry. “It does make some price provisions for locally procured materials,” says Al-Husseini. “But in general, technical specifications, costs and delivery schedules are the critical factor in granting contracts.”

The company’s new business development division is the main unit responsible for enhancing local private sector participation in the oil and gas economy. Its remit is to increase the range and quality of goods available in the local market by facilitating the growth of new and existing manufacturers in the oil and gas industry through local and/or international investment. It also aims to increase the range and quality of oil field services by encouraging the development of reliable small and medium-sized service enterprises that will lead to the transfer of technology and know-how to the kingdom.

The new business division has set up a dedicated entity - the local enterprise development division - to provide active support to investors interested in establishing local enterprises for equipment manufacturing and oil field services. This has created a support programme administered by the new business division to actively facilitate and encourage the establishment of oilfield service enterprises in the kingdom.

The focus on local resourcing extends well beyond the kingdom’s borders. Aramco also expects the contribution from sourcing and procurement of materials in Asia to increase by up to 50 per cent. In 2006, it opened offices in Shanghai and Kuala Lumpur, designed to focus on the strategic sourcing of companies involved in manufacturing and contracting materials.

Equal partners

Aramco’s focus on partnership throughout its supply chain will remain a critical component of its business strategy. The lessons it has learned over many years of project management have taught it to partner with its contractors and suppliers rather than maintain an adversarial posture.

“This spirit of co-operation has been instrumental in managing its projects in an efficient manner and avoiding the pitfalls of those who choose an adversarial approach to project management,” says Al-Husseini.

Supply chain management

The concept of supply chain management has seeped into Saudi business culture. “Supply chain management is vital for all major projects because it sets the rate at which they can be executed,” says Sadad al-Husseini, former executive vice-president of exploration and production at Aramco.

“Materials scheduling must be carefully synchronised with engineering design, the selection and deployment of subcontractors, site preparation, construction infrastructure and the provision for critical skills and personnel.”

In 2005, Aramco’s materials supply division launched a four-year drive to improve supply chain management. One strategy included outsourcing the inventory and related non-core activities to the local market to promote the national economy and create more job oppor-tunities for Saudi nationals.

It nominated four local companies - Al-Barwadi, Al-Dossary, Al-Mohaidib and Al-Fozan - to be the main suppliers of building materials over the next 10 years. More than 4,000 line items will eventually be covered by the agreements.

Since 1 January 2007, Exel Saudi Arabia, a joint venture of the local Olayan Group and the UK’s Exel, has been providing comprehensive logistical services to Aramco under a 10-year logistics contract.

For both local and foreign manufacturers and suppliers, Aramco operates a system enabling it to classify, approve and prequalify local and foreign manufacturers and vendors. Depending on the company’s requirements for particular products, the manufacturer can either sell directly to Aramco or go through a local agent. Sometimes Aramco purchases materials directly from foreign manufacturers or suppliers if the amounts are less than $10,000.

Wish List

Saudi Aramco has identified manufacturing opportunities for equipment and materials used at its oil and gas facilities:

Batteries/rectifiers/power supplies

Boilers/heat exchangers/chillers

Catalysts

Circuit breakers/programmable logic controllers

Compressors

Drill bits

Drilling mud additives and well stimulants

Hoses

Instrumentation

Oil country tubular goods casing, tubing and accessories

Packers and wire line accessories

Pipe fittings/wrap

Pumps

Speciality chemicals

Turbines

Valves and related accessories

You might also like...

Algeria signs oil deal with Swedish company

19 April 2024

Masdar and Etihad plan pumped hydro project

19 April 2024

Ewec signs Ajban solar PV contract

19 April 2024

Contractor orders compressors for onshore project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.