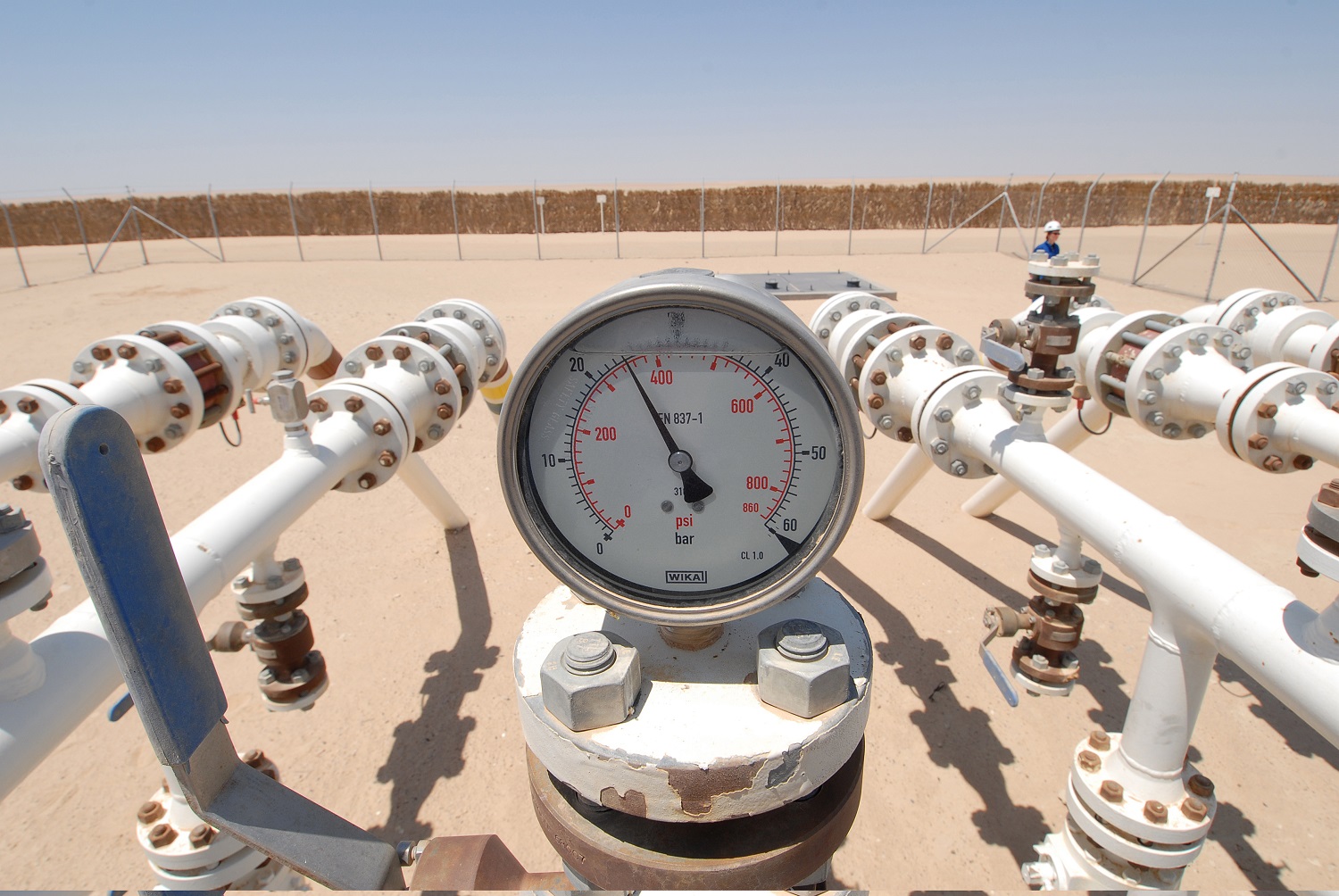

As hydrocarbons become more sour, national oil companies need to adapt their downstream facilities

The delays to Saudi Aramco’s Wasit Gas Development project due to the unusual density of the sulphur is a good example of how the Middle East’s energy resources are changing.

As well as sour gas, more heavy sour crude is now being pumped by the region’s hydrocarbon producers. Handling and processing sulphur are skills that are becoming more sought after by national oil companies (NOCs) in the Middle East.

If the sulphur contained in an oil or gas field has a high density, then the usual solution is to inject a chemical cocktail into the field in order to lighten it to a level where it can be easily transported.

Most international oil companies (IOCs) offer technology to the NOCs to tackle upstream sulphur, but it is the downstream oil and gas industry that is beginning to offer the most opportunities in the Middle East.

The majority of grassroot refineries and upgrades of existing facilities being planned in the GCC will involve some form of sulphur treatment facilities. These facilities will allow sulphur to be separated, processed and sold on the international market.

According to regional projects tracker MEED Projects, there are more than $31bn-worth of refining projects in the GCC at the planning, design or tender phase that will that require sulphur handling or processing facilities to be constructed.

Most of the facilities will involve converting sulphur into granules, which are then stored in silos before being shipped to customers.

The packages that require sulphur handling will make up a small percentage, about 10 per cent of the $31bn-worth of refining schemes, but this still offers technology providers the potential to win multimillion-dollar contracts.

“There is no doubt that the market is changing in the Middle East due to the increased sulphur content in the hydrocarbons,” says a source from a technology provider. “Admittedly this means that the cost of transporting and processing oil is increased, but selling the sulphur can offset much of the costs.”

The good news for refiners in the GCC is that global sulphur demand is rising and is expected to increase to more than 70 million tonnes a year by 2015 driven by strong growth demand from Asia. The bad news is the price for a tonne of sulphur has been less than $200 since 2008.

Despite the difficulties in processing, sulphur is a versatile product and has uses across several sectors, including the sulphuric acid, fertiliser, pharmaceutical and concrete industries.

It is debatable whether selling the sulphur from sour crude will offset the processing costs, but heavier sourer crude is becoming more commonplace and the region’s hydrocarbons sector has to adapt accordingly.

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time to revise MGS package bids

18 April 2024

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.