The first shipment of products from the Pearl GTL plant in Ras Laffan marks the culmination of long and successful partnership between the UK/Dutch Shell Group and the Qatari government

The first shipment of products from the Pearl gas-to-liquids (GTL) plant at Ras Laffan Industrial City on 13 June 2011 marked the culmination of more than 35 years of research for UK/Dutch Shell Group and another major step in Qatar’s industrialisation drive.

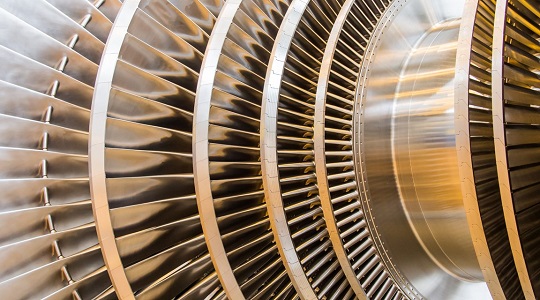

With a capacity of 140,000 barrels a day (b/d) of GTL products and 120,000 b/d of associated upstream products, the Pearl GTL is the largest facility of its kind in the world.

The project was built under a development and production sharing agreement (DPSA), signed between Shell and the government of Qatar in 2004, following a heads of agreement in 2003 and a memorandum of understanding in 2002.

Long journey to extract gas

The Pearl GTL project encompassed the development of a block in Qatar’s North Field, transporting and processing the gas to extract natural gas liquids and ethane and the conversion of the remaining gas into liquid hydrocarbon products, including naphtha, kerosene and gasoil.

With Bintulu in Malaysia, we had proven technology that we wanted to show on a commercial scale

Andrew Brown, Shell Qatar

For Shell, the journey began in 1973 when it began researching the production of non-crude-based transportation fuels. Initially, the oil major focused on coal, before turning its attention to gas in the 1980s. From then on, progress has been rapid. By 1983, it had built a pilot GTL plant in Amsterdam. Just three years later, Shell had inked a deal to build its first commercial GTL plant in Bintulu in Malaysia and a 12,500 b/d plant was commissioned in 1993. It took several years to stabilise production, but by 2001, Shell believed it could develop a world-scale GTL plant. It found a natural partner in the Qatari government, owner of the world’s largest offshore non-associated natural gas field, with estimated reserves of more than 900 trillion cubic feet of recoverable gas.

“With Bintulu in Malaysia, we had proven technology that we wanted to show on a commercial scale,” says Andrew Brown, executive vice-president of Shell Qatar and managing director of the Pearl GTL. “Meanwhile, Qatar was saying we would like to become the GTL capital of the world. It gave us the opportunity to use the technology we had been developing and gave us the opportunity to access the enormous gas resources of the state of Qatar and together with Qatar Petroleum to create a project of significant value attached to it.”

A year before signing the letter of intent for the Pearl GTL project, Shell had signed a memorandum of understanding to develop another major gas project at Ras Laffan – the Qatargas 4 liquefied natural gas (LNG) train, which started up in February 2011. The two schemes have cemented what promises to be a long and profitable partnership between Shell and Qatar.

The Pearl GTL represents a massive scale-up from the Bintulu plant, which today has a capacity of 14,700 b/d. The two trains in Ras Laffan are five times larger than the single train at the Malaysian facility. It is the largest industrial project ever launched in Qatar and at peak construction had 52,000 workers on site.

At an estimated cost of $18-19bn, the capital investment for Shell in the Pearl GTL has been immense. Under the terms of the DPSA, the oil major was responsible for the entire cost of the project.

“We didn’t use project finance because it was new technology,” says Brown. “No one had ever done GTL before of this size, we felt we could borrow against Shell’s balance sheet at a better rate than the completion risks that maybe a GTL project entailed.” It is the largest amount the company has ever invested in a single project.

But the absence of a gas transfer price makes the project hugely competitive. The Pearl GTL receives its gas feedstock for free and as a result its margins are far larger than those at most crude-based refineries with which it competes.

The integrated operating cost is just $6 a barrel of upstream production. Shell is allowed to recoup the operational costs and capital costs from the sales revenues before sharing the profits with the government. Analysts say the plant could be paid off within five years. Brown says that at $70 a barrel, the Qatargas 4 and Pearl GTL projects will generate an estimated $6bn a year of free cash flow for Shell. The combined investment in the two schemes was $20bn-21bn.

The attraction of the project for the Qatari government is equally sizeable. The Pearl GTL forms part of Qatar’s two decade-long drive to exploit its hydrocarbons resources. Last year, saw the country’s investment in LNG infrastructure reach an historic milestone, with capacity hitting 77 million tonnes a year. This followed the opening a couple of years earlier of the Qatar-UAE/Oman gas export pipeline.

GTL offers an alternative way for Qatar to monetise its giant gas resources from pipelines and LNG exports, which target industry and utilities, providing the opportunity to diversify into transportation fuels.

GTL production is a much more flexible market than the gas export industry. LNG producers are constrained by the nature of the product, which has a fixed long-term supply chain and requires specialist vessels and regasification terminals or pipelines.

Any further development and expansion [of the Pearl GTL] is up to the state of Qatar

Andrew Brown, Shell Qatar

GTL products by contrast are stable and can be carried in standard product carriers to any market under short-term or spot deals. The end-users are potentially limitless and producers can respond easily to changing demand. A further advantage of GTL products is that they are replacements for oil-derived products, which makes them especially attractive when oil prices are high.

They are also able to command a premium as they are cleaner fuels than their oil-based counterparts. With governments tightening restrictions on emissions, demand for high-quality, ultra-keen fuel is forecast to increase strongly in the years ahead.

The Pearl GTL is not Qatar’s first GTL production plant. Oryx GTL, also located at Ras Laffan, started up in late 2006. It has a capacity of 32,400 b/d of GTL products. But it is the sheer size of the Pearl GTL scheme that sets it apart from other projects around the world and has firmly place Qatar has the world leader in GTL production.

Its partnership with Shell has provided it with access to proprietary technology, expertise and a well-established distribution network and in about 30 years time state energy firm Qatar Petroleum will take control of the asset. Shell has filed more than 3,500 patents for its GTL technology.

The Pearl GTL project has not been without its challenges though. Construction work on the onshore site began at the height of a GCC-wide building boom, which led to major inflation in the prices of materials and labour. That was then followed by the global financial crisis, which hit many contractors and suppliers hard. The scale of the operation was also a major logistical challenge: some 2 million freight tonnes of materials had to be imported and power lines had to be dismantled to transport the plant’s giant reactors.

Safety record

For the Shell management, the biggest challenge was managing safely a workforce of 52,000, but it was able to successfully do this by creating a culture of health and safety. The project set new records for drilling and the number of hours worked without a lost time injury.

“Within Shell, Pearl is famous for three things,” says Brown. “Its safety culture, the project delivery and the ability to keep control of the budget and schedule of a megaproject. A lot of the processes are running at extreme conditions, but all of it has worked first time round. Typically, new technology projects, megaprojects have massive problems at start-up and this project hasn’t.”

The first train of the Pearl GTL is already producing and the second train is due to start up by the end of 2011 and ramp up production during 2012. There is a room at the site for two further trains, but as yet there are no firm plans to expand the facility.

“Any further development and expansion [of the Pearl GTL] is up to the state of Qatar,” says Brown. “There is the potential to expand, but we can only really do so when we have the contract from the state of Qatar.”

In 2005, the Qatari government placed a moratorium on new developments on the North Field, in order to study the impact that the series of megaprojects launched since 1991 has had on the reservoir. It is not unlikely to be lifted before 2014.

For now, the focus is on ramping up production at the existing plant and bringing the second train on line. But with demand growing world-wide for clean fuels, it is likely further projects will follow.

You might also like...

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

Jubail 4 and 6 bidders get more time

26 April 2024

Amiral cogen eyes financial close

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.