For more than 80 years, since Saudi Arabia’s first commercial oil discovery, Saudi Aramco’s geologists and petroleum engineers have studied the layers of rock and sediment collected while drilling for clues to the hydrocarbons wealth below the surface.

For more than 80 years, since Saudi Arabia’s first commercial oil discovery, Saudi Aramco’s geologists and petroleum engineers have studied the layers of rock and sediment collected while drilling for clues to the hydrocarbons wealth below the surface.

Today, that task is just one of many that is being expedited by big data analytics, machine learning and artificial intelligence (AI) – replacing time-consuming processes with a dynamic new approach.

A short walk from that first discovery at Dammam Well Number 7, also known as the Prosperity Well, is an expanding team of AI experts and other specialists who are increasing Aramco’s discoveries and recoveries while driving cost savings, boosting efficiency and seeking to cut emissions.

The company is championing AI-inspired solutions to capitalise on the billions of data points collected over the decades through a new “corporate digital factory” that is staffed by data scientists, machine learning experts and other specialists who are tasked with seeking out operational challenges and developing intelligent solutions to help improve Saudi Aramco’s business performance.

Collaboration with different operational teams helps to anticipate issues, automate processes and work more efficiently. This has transformed the decision-making process and helped to improve business outcomes.

Project management

The fast-changing nature of AI has also required Aramco to shift to a more agile project management approach and away from the “waterfall” model of sequential project planning, where an initial scope is designed and then delivered a few years later – by which time it may no longer be needed.

Instead, Aramco’s digital transformation team is now approaching projects by working closely with the relevant part of the business, or with a customer, in short, intensive “sprints” to ensure goals and outcomes are better aligned.

This has enabled teams to deliver projects more quickly and, as it involves the end-users throughout the process, it has been critical to the successful delivery of several digital projects on time and within budget.

The more collaborative approach means the project that is ultimately delivered is more likely to still be relevant and fit for purpose.

| Learn more about subscribing to MEED.com The #1 platform for business news and intelligence trusted by 1,000+ leading, global brands |

Business impact

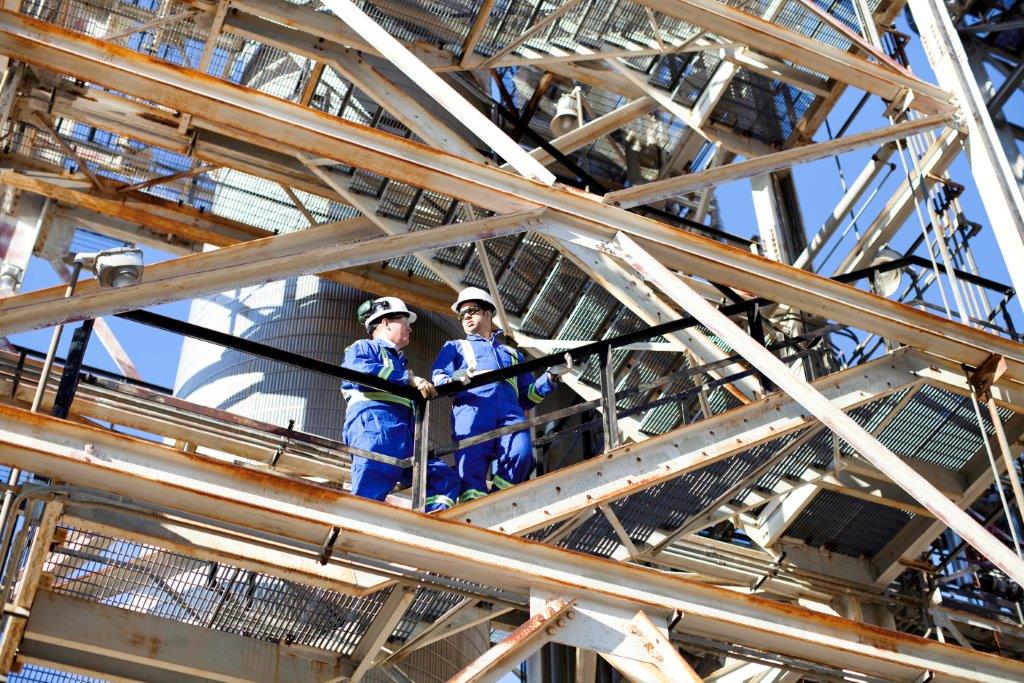

The digital transformation drive is improving Aramco’s entire business. It has helped to reduce costs and deliver environmental and safety benefits throughout the energy value chain.

The upstream side of Aramco’s business has been an early adopter of AI technologies. The firm’s geologists have deployed AI tools to tap into the data collected from more than a million feet of rock, much more quickly than would have been possible in the past. This has helped improve the understanding of the petro-physical properties of the terrain where exploration and drilling take place, which makes for much quicker decision making.

The company also uses big data analytics and machine learning to improve the performance of reservoirs deep below the surface.

Millions of dollars have been saved through the use of high-performance computing and advanced AI techniques that optimise field development plans and well trajectories. This has helped Aramco to maximise recovery, ensure reliability, reduce costs and minimise the environmental impact of its operations.

Millions of dollars have been saved through the use of high-performance computing and advanced AI techniques that optimise field development plans and well trajectories. This has helped Aramco to maximise recovery, ensure reliability, reduce costs and minimise the environmental impact of its operations.

Big data is also being deployed to predict and prevent drilling challenges such as stuck pipes, which can produce costly setbacks. This technology uses AI and machine learning to help drilling crews detect the warning signs that precede a pipe becoming lodged, leading to an overall improvement in drilling performance.

AI has also been deployed to detect the health of vital equipment such as steam traps. A model was developed to check the status of these special purpose valves using infra-red images.

When coupled with other new technologies under deployment, including robots and unmanned aerial vehicles, this has resulted in significant improvement in the efficiency and reliability of steam systems currently in use.

Other AI-based tools are being used to inspect pipelines and difficult-to-access tank roofs, using advanced image analytics. This type of technology has also been leveraged to improve the quality monitoring of refined products and prevent flaring incidents.

On the safety front, Aramco has analysed years of data to identify and avoid potential risks.

Digital solutions are helping to rapidly transform processes across the operational spectrum. While the tools used to achieve that transformation are being guided by AI, this is ultimately more about business than technology.

The pace of the transition that is under way in the wider energy industry has created an urgent need for such data-driven solutions, which can be conceived and delivered with speed – solutions that anticipate as well as react, helping to improve business operations and performance at a pace not previously seen.

In that sense, digital technology is accelerating transformation, preparing the oil and gas industry for the challenges of tomorrow and enhancing Saudi Aramco’s operations today.

You might also like...

PIF and Acwa Power take next solar round

16 April 2024

Etihad to decide Ghalilah 1 IWP capacity

16 April 2024

EGA and Masdar to sign deal

16 April 2024

Saudi sports ministry tenders Dammam stadium works

16 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.