The regions industrial changemakers have cemented their credentials as globally powerful players

When the oil boom started to transform the Gulf in the mid-1970s, the more far-sighted regional policymakers and business leaders began to think seriously about capturing added value from their hydrocarbons endowments. The idea was to ensure that their collective exposure to a single commodity crude oil would not overburden their economies.

Industrial diversification remains a mantra to this day. Saudi Arabias Vision 2030 programme, unveiled in 2016, aims to reposition the kingdoms economy away from its dependence on oil and gas.

Feedstock advantage

The Gulfs industrialisation effort stretches back to the late 1960s, when Bahrain and Kuwait started developing heavy industry sectors deploying the regions energy feedstock advantage.

Bahrain launched the Gulfs first aluminium smelter, operated by Aluminium Bahrain (Alba) in 1971. Three years later, Qatar set up Qatar Steel. Not to be outdone, Saudi Arabia set out its own industrialisation strategy with the energetic support of its leadership. Within three years of the 1973 quadrupling of oil prices, Saudi Arabias King Khaled bin Abdulaziz al-Saud had issued a royal decree establishing Saudi Basic Industries Corporation (Sabic). It would become one of the Middle Easts most powerful diversified industrial conglomerates, with products ranging from petrochemicals to steel and fertilisers.

The key figure driving the kingdoms industrialisation effort was the monarchs half-brother, the then-crown prince and future king Fahd bin Abdulaziz. The ambitious crown prince emerged as one of the Gulfs first modernisers, with a keen appreciation of the importance of developing downstream industries. With Sabic established and focused on import substitution projects, Fahd then played a vital role in setting up one of the most important agents of change in the Middle Easts industrial landscape: the Royal Commission for Jubail & Yanbu (RCJY). Its twin cities helped build up the Gulfs industry base and avoid the dreaded Dutch disease.

The Saudi leadership chose the most talented for the top roles in these nascent industries

Sabic and the RCJY are the two entities most responsible for developing Saudi Arabias industrial prowess. The Royal Commission today led by Prince Saud bin Abdullah Thunayan al-Saud is mandated to develop a fully integrated downstream sector. Prince Saud, and his predecessors at the helm of RCJY, such as Prince Abdullah bin Faisal bin Turki who went on to head up the Saudi Arabian General Investment Authority have played a decisive role in fleshing out those ambitions.

From the outset, the Saudi leadership chose the most talented for the top roles in these nascent industries. Ghazi al-Gosaibi, then minister of industry and electricity and a future Saudi ambassador to the UK was the formative figure in Sabics early development in the 1970s. He helped ensure that the company while wholly state-owned initially had a corporate mindset, focused on generating returns. He also ensured that the company was insulated from direct royal influence, something that has helped ensure its success.

Sabic was also the launchpad for one of the Gulfs most prominent agents of change, its first CEO Abdulaziz al-Zamil, a dynamic figure from the Saudi merchant business community, who had trained in the US as an engineer. He was chairman of Sabic in the crucial years of its expansion in 1983-95. That experience was then transferred to the private sector as he returned to Zamil Group Holding Company in 1995, and he soon branched out into petrochemicals, establishing major entities such as Saudi International Petrochemical Company (Sipchem) and Sahara Petrochemicals Company.

Extending reach

The Gulfs industrial diversification champions soon forged links across borders; for example, Sabic is an investor in Alba, which more than four decades on is continuing its expansion with the development of a sixth potline. This will make Alba the largest single-site smelter in the world, taking total production capacity to about 1.5 million tonnes a year (t/y).

GCC polymers production

The UAE has likewise viewed diversification as essential to its future economic growth. Dubai Aluminium (Dubal), now part of Emirates Global Aluminium (EGA), is another aluminum group that has benefited from the exploitation of abundant and cheap energy supplies. Founded in 1979, Dubals Jebel Ali operation encompasses a 1-million-t/y aluminum smelter, one of the worlds largest single-site primary smelters.

EGAs core operating assets, Dubal and Abu Dhabis Emirates Aluminium, merged in 2014. Their combined capacity is 2.4 million t/y, putting EGA among the five largest primary aluminium producers in the world. Underscoring the linkages across Gulf economies, last year EGA announced the first licensing of its proprietary smelting technology to Alba.

The other significant industrial agent of change in the UAE is Senaat, a large investment holding company formed in 1998 out of General Holding Corporation and its wholly owned subsidiary Abu Dhabi Basic Industries Corporation. It is mandated by the Abu Dhabi government to operate in the four main industrial sectors outlined in its Economic Vision 2030, serving as a catalyst for industrial activity. It is the parent company of Emirates Steel and has invested more than AED19bn ($5.2bn) since 2004, creating an integrated network of national industries.

Senaat chairman Hussain al-Nowais is one of the key Emirati business leaders charged with steering the UAEs industrial diversification effort. Besides his responsibilities at Senaat, he is also chairman of National Petroleum Construction Company, Emirates Steel and the Khalifa Fund for Enterprise Development.

Metals cluster

Emirates Steel was established in 2001 with the aim of kickstarting a local steelmaking industry. It is a core part of Senaats plan to develop a metals cluster in the emirate and is the only integrated steel plant in the UAE, utilising the latest rolling mill technology to produce rebar, wire rod and heavy sections. The first half of 2016 saw the sale of 1.8 million tonnes of finished steel products. It aims to build on this platform to develop other margin value-added products that are more resistant to volatile demand.

The achievements of EGA and Senaat underscore the impact that the Middle Easts diversification champions have made. The newer entrants are continuing the pioneering path set by the likes of Alba and Sabic in the 1970s. Their key challenge over the next decade is to branch out from investments in primary industries, which are exposed to fluctuating export markets, and develop downstream products that can be sold at higher prices.

GCC polymers capacity

Sabic for one is not resting on its laurels. Now the Middle Easts biggest listed company, it has become the worlds fourth-largest petrochemicals firm, having established a base in Europe and acquired the US GE Plastics. In January 2017, it bought UK/Dutch Shell Groups 50 per cent share in Saudi Petrochemical Company (Sadaf), a joint venture located in Jubail.

The Middle East petrochemicals industry has grown in leaps and bounds since the first plant began operations in 1981. In 2016 alone, projects worth $13bn were announced in the Middle East, which will add 8 million t/y of capacity between 2020 and 2024.

The regions total petrochemicals capacity reached 150 million t/y in 2017, according to the Gulf Petrochemicals & Chemicals Association. Saudi Arabia is the Gulfs largest producer with 99.1 million t/y of capacity, representing a 66 per cent share of the regional total.

Firms such as Alba, Dubal and Sabic have cemented their credentials as global players. The challenge for the regions industrial changemakers now is to move away from the immediate areas of competitive advantage and extend further down the supply chain into areas such as plastics, which command higher prices and contribute more job opportunities.

Historical milestones

? 1971: Bahrain opens the Gulfs first aluminium smelter, operated by Aluminium Bahrain (Alba)

? 1974: Qatar Steel (formerly Qasco) established as the first integrated steel plant in the region

? 1975: Saudi Arabias Royal Commission for Jubail & Yanbu set up

? 1976: Saudi Basic Industries Corporation (Sabic) created by royal decree

? 1998: Senaat formed out of General Holding Corporation and its wholly owned subsidiary Abu Dhabi Basic Industries Corporation

? 1999: Abdulaziz al-Zamil launches Saudi International Petrochemical Company (Sipchem)

? 2001: Emirates Steel established

? 2014: Dubai Aluminium and Abu Dhabis Emirates Aluminium merge

You might also like...

UAE rides high on non-oil boom

26 April 2024

Qiddiya evaluates multipurpose stadium bids

26 April 2024

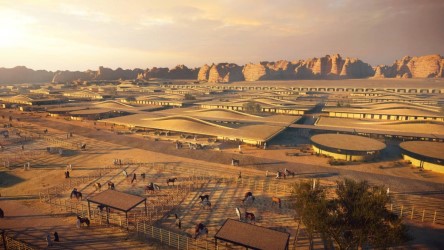

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.