Prequalification documents for the Al-Zour petrochemicals complex, which will include a detailed scope for the project, are due to be issued next week, according to industry sources.

Kuwait Integrated Petroleum Industries Company (KIPIC), the project client, has already announced that companies have until 20 September to submit prequalification bids for the main engineering, procurement and construction (EPC) contracts.

KIPIC has invited contractors to prequalify for two sections of the complex; the olefins 3 block, estimated to be worth $1.5bn, and the aromatics 2 plant, valued at $5bn.

The third package in the Al-Zour petrochemicals complex is a $1.3bn gasoline block. An invitation for expressions of interest (EOI) is expected to be issued by the client in August this year.

The UK’s Wood Group is carrying out the front-end engineering and design (feed) work for the project.

Honeywell UOP was announced as the technology provider for the project in November.

The petrochemicals facility will be integrated with the $17bn Al-Zour New Refinery Project. When completed, it will be the largest integrated refinery and petrochemicals plant in Kuwait.

It will produce aromatics and propylene and is a key part of Kuwait’s broader industrial strategy.

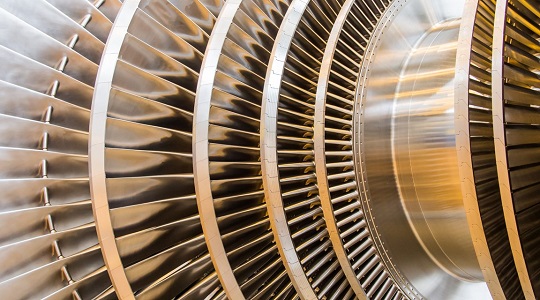

The petrochemicals project includes a 50,000 barrels-a-day (b/d) residue fluid catalytic cracking (RFCC) complex with ethylene and propylene recovery, a 24,000 b/d gasoline desulphorisation unit and two units to treat propane for propylene production.

It will be capable of converting butane to isobutane and producing clean-fuels blending components including methyl tert-butyl ether (MTBE).

The facility will include a 66,000 b/d continuous catalyst regeneration (CCR) platforming unit with a 74,000 b/d naphtha hydrotreater to make gasoline blend stock.

The aromatics complex will have the capacity to make 1.4 million tonnes of paraxylene a year.

A propane dehydrogenation unit will produce 660,000 tonnes a year of polymer-grade propylene.

Feed work for the planned petrochemicals plant was initially expected to be completed at the end of June 2018, but has been delayed.

The main EPC contracts for the new refinery project were awarded in mid-2015 and are under execution.

On 16 December, KIPIC denied MEED reports that the refinery project was delayed. It said work was proceeding on schedule and the refinery would start operations in May 2019.

In April, Khaled Mahdi, secretary general of Kuwait’s Supreme Council for Planning & Development, said the project had been delayed and is now targeting completion by December 2019.

| This article has been unlocked to allow non-subscribers to sample MEED’s content for FREE. MEED provides exclusive news, data and analysis about the Middle East every day. Subscribe to MEED to have full access to Middle East business intelligence. Click here |

You might also like...

Amiral cogen eyes financial close

26 April 2024

Lunate acquires 40% stake in Adnoc Oil Pipelines

26 April 2024

Saudi Arabia's Rawabi Holding raises SR1.2bn in sukuk

26 April 2024

Iraq oil project reaches 70% completion

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.