Kuwait-based Spetco International Petroleum has submitted the lowest bid – KD 84m ($277m) – for the Kuwait Oil Company (KOC) project to build a gas sweetening facility in West Kuwait.

Just two companies submitted commercial bids for the project out of 29 that prequalified. Bids were submitted ahead of the 3 June deadline.

The contract consists of two portions: the gas facility itself and a sulphur recovery unit (SRU).

Although the two parts are being tendered under a single contract, they use different project financing models. The gas sweetening facility is being built using the engineering, procurement and construction (EPC) model, and the SRU the build own operate (BOO) model.

According to the scope of work, the facility will be built to deliver 120 million standard cubic feet a day (MMSCFD) of sweet gas using sour gas streams from upstream processing units, with a varied hydrogen sulphide concentration of 4 per cent (mole) and carbon dioxide of 10 per cent (mole).

The facility will be installed at Booster Station BS-171 West Kuwait and built as an amine solvent-based gas treating unit.

Amine gas treating, also known as amine scrubbing, refers to a group of processes that use aqueous solutions of various alkylamines (commonly referred to simply as amines) to remove the acid gases and other toxic contaminants from raw sour gas streams.

The facility will consist of two identical gas processing trains, each with a capacity of 60 million stand cubic feet a day (SCFD).

The facility will be fed by raw sour gas contaminated with heavy hydrocarbons, suspended solids (in the form of black powder), salt water, compressor lube oils and pipeline treating chemicals. This will be cooled to a lower temperature to remove hydrocarbon liquids and then passed through a suitable pre-treatment system. The gas sweetening facility will be designed for zero flaring.

KOC has stipulated that the winner of the contract will be required to develop a gas dispersion flaring model based on simulation results, capacity and tum-down, using a quantitative reliability assessment. The SRU will consist of two separate trains.

According to the scope released by KOC, the contractor will be required to provide tie-in facilities for the two SRU trains. They will also be responsible for the procurement, supply, installation, construction, testing, pre-commissioning, commissioning and performance testing of the SRU and associated piping.

Each train will have the capacity to handle 100 metric tons a day (TPD) of molten sulphur.

You might also like...

Qiddiya evaluates multipurpose stadium bids

26 April 2024

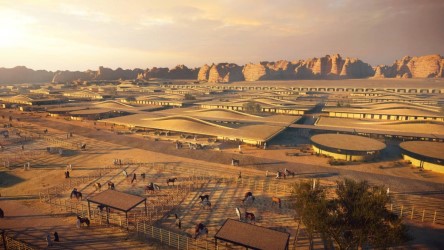

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.