Four international companies and groups have been invited to submit bids by 12 November for the contract to build the sulphuric acid plantat Ras al-Zour. The project, part of the $2,000 million phosphate and fertiliser project, is being developed by the Public Investment Fund and Saudi Arabian Mining Company (Maaden - MEED 9:9:05).

The four are: Oslo-based AkerKvaerner; Paris-based Technip; a Dutch/Finnish joint venture of BatemanEngineeringand Outokumpu; and SaudiOgerwith the UK's Simon- Carvesand Turkey's Tekfen. The scope of works for the estimated $450 million-500 million engineering, procurement and construction (EPC) contract calls for the construction of two sulphuric acid trains with combined capacity of 450,000 tonnes a year (t/y) as well as absorption towers and a cooling system. The sulphuric acid will be mixed with phosphoric acid and ammonia to process phosphate into diammonia phosphate (DAP). Tenders for the three ammonia, phosphoric acid and DAP plant packages are expected to be issued in early November (MEED 5:8:05). The phosphate feedstock will be sourced from the Al-Jalamid deposit in the northwest and transported via the planned minerals railway to Ras al-Zour. A team of Canada's SNC Lavalin, with the US' Jacobs Engineering, and Australia's WorleyParsons are bidding for the project management consultancy PMC contract on the phosphate complex (see page 24). www.meed.com/petrochemicals

You might also like...

UAE rides high on non-oil boom

26 April 2024

Qiddiya evaluates multipurpose stadium bids

26 April 2024

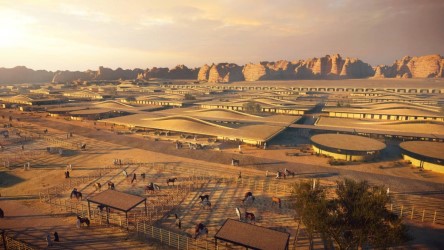

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.