Q&A with Marjo Louw, Sasol country president, Qatar

Where did the gas-to-liquids (GTL) process originate?

The concept of gas conversion from either natural gas or coal was devised in the early 1920s by two Germans called Franz Fischer and Hans Tropsch.

At the time, Germany was short of fuel, so they decided on a process involving the gasification of coal, and then to liquid fuels. This method became known as the Fischer-Tropsch process.

What is the history of Sasols involvement in the production of GTL?

In the late 1940s, South Africa had no crude oil of its own and a shortage of funds, so the government sought to develop a strategic project for the supply of fuels to the South African market.

In the 1950s, it established a factory in a town called Sasolburg, using high-temperature technology to produce coal-to-liquids [CTL].

There were strategic reasons for its development, but the concept at the time was that it had to be profitable. It was discovered that lots of other chemicals could be produced using this process, such as ammonia, which can be used to make fertilisers, as well as other products such as solvents.

During the international oil crisis in the 1970s, it became more difficult to import oil and refined products, so there was greater pressure to produce fuels locally. The government decided to privatise Sasol and, in 1979, it was listed on the Johannesburg Stock Exchange.

There was just one smallish plant initially; this was followed by the completion of the Sasol 2 and Sasol 3 synfuels and chemicals complexes during the early 1980s.

These two plants, located at Secunda, are now jointly called Sasol Synfuels. Each of the facilities produces 80,000 barrels a day (b/d) of fuels.

By the early 1990s, the world market was opening up for Sasol. High-temperature gas conversion provides a range of products that you do not get with low-temperature technology, and from 1990 onwards we started to extract more and more chemicals.

In 2003, Sasol was listed on the New York Stock Exchange.

How did you come to invest in Qatar?

It was at that time that we started to develop a low-temperature gas conversion technology suitable for diesel production that is unique to Sasol. We decided against its use in South Africa, but it was ideal for the conversion of natural gas in Qatar.

They had just made a big gas find, and the development of gas was part of the former emirs 2012 Qatar National Research Strategy, which later became the Qatar National Vision 2030. According to the emirs vision, there would be a push for the production of liquefied natural gas, but gas development would also include the production of GTL in the monetisation of the countrys huge gas reserves. Discussions with Qatar started in 1996-97.

Were there any risks involved in developing a GTL project in Qatar?

Not operating this version of the technology on a commercial scale meant that there was some technical risk. Different versions of the technology were proven on a much larger scale. But the systems and the type of reactor were new.

Why did Qatar choose Sasol?

Qatar evaluated several different possibilities for GTL. Sasol had the most experience, so Qatar Petroleum chose us to continue. We signed a joint venture around 2002, the plant was built by 2006, and it became fully operational by 2007.

How much GTL is your Qatar plant producing, and did you have any issues with it?

We had some unexpected technical challenges with the big scale up, which were well reported. But now the plant is running at its maximum capacity of 32,400 b/d. We have an excellent safety record and have not had a lost time incident for more than 800 days. On numerous occasions over the past two years weve been running at above design capacity and, on average, we run at close to 90 per cent of capacity.

Is the plant financially viable?

It was justified in the early 2000s at an oil price of less than $20 a barrel, so it shows you what can be done.

What products does the plant produce? What differentiates them from other refined fuels and where are they sold?

The main products are diesel and naphtha. Diesel accounts for about 75 per cent of total production. It is more paraffinic than most diesels and more environmentally friendly. It has a high cetane value, which measures the energy it delivers. It is also very low in sulphur certainly less than 5 parts per million (ppm) and usually close to zero.

The diesel is mainly exported to northwest Europe, and in the recent past to elsewhere in the Middle East. Its not being sold as a finished diesel; it carries a higher value if you sell it as a high-quality blend stock. Typically, it is acquired by blenders to meet European standards on sulphur content, which tend to be less than 10ppm.

We are working in Nigeria with Chevron and Nigerian National Petroleum Corporation to build a GTL plant

Marjo Louw, Sasol

We also produce some naphtha, which is a very good cracker feed, and which is exported to South Asia and the Far East. Were getting a premium on the naphtha, but the percentage varies on a shipment-by-shipment basis. And we produce some liquefied petroleum gas, which is piped for use in Qatar. We chose not to produce jet fuel in Qatar, but it is possible and we have approval to use GTL in jet fuel up to a maximum of 50 per cent.

What other operations do you have?

The fuels we produce in South Africa are fully fungible with regular refinery fuels. In the Highveld of South Africa, any fuels you buy will contain Sasol fuels. Sasol has agreements with all the OEMs [original equipment manufacturers] and we have also received approvals for jet fuel. Since 1999, virtually all the flights out of Johannesburg have used up to 50 per cent synthetic fuel [liquid fuel from coal, natural gas, oil shale, or biomass] and usually more than that. We are the only company with full OEM approval for 100 per cent synthetic jet fuel.

What other operations are you developing?

Today, we are working in Nigeria with [the US] Chevron and Nigerian National Petroleum Corporation to build a GTL plant. We are busy with commissioning at the moment. It will be completed by the end of this year and will reach full capacity by mid-2014. We are also approaching a final investment decision in Uzbekistan for a larger plant than in Qatar, based on the same principles. We are working in a joint venture with Uzbekistans national oil company and [Malaysias] Petronas. The front-end engineering and design [feed] is almost complete and were in the process of evaluations for the engineering, procurement and construction phase.

Are you looking at any other markets?

We are also looking at two more GTL facilities in the US, both in the same premises in Louisiana. The feed has started, and were probably heading for a final investment decision in the next two to three years. Sasol currently has chemical facilities on the site and we are looking at building an additional chemicals complex with a cracker and downstream units.

We have also finished a feasibility study in Canada and it is looking good. We are continuing with the permitting process. Due to resource constraints, well be doing the feed at a later date. I dont like to put a time to it; its partly dependent on how fast we move forward.

Are there other potential locations where GTL might be viable?

We are doing a screening of a number of potential partners where the model could work, but we have to look at them on a site-by-site basis. There are a number of possibilities, but Im afraid I cant be more specific than that.

How do you see the GTL market developing in the future?

Sasol sees great potential for GTL. In North America, there are numerous opportunities because of the countrys strategic position, new gas finds and the disassociation of the gas price from the oil price. Its an energy-short environment with an abundance of gas and a need for refined fuels.

How do you ensure that a GTL project is viable?

Whether a project is viable or not is highly dependent on what price you get for your product and what price you pay for your feedstock. Its a bit like asking whether crude will be profitable in the future without taking into account that the cost of production depends on where it is located and can vary from $10 to $115 a barrel. GTL production is not constrained by the size of market. At the very least, it will sell for the same price as the equivalent refined oil in terms of sulphur ppm.

At the moment, there are five synthetic fuel plants in the world: two in Qatar, one in Malaysia and two in South Africa. Theyre all doing well. The technology itself is well established. The challenge lies in the operation of a combination of technologies. On the other hand, reaching the optimum running level takes time, so it can be a while before the value is maximised.

GTL is a great way of making money from unmonetised gas and promoting product diversification. There are opportunities in North America and in places such as Uzbekistan, where theres a need for transport fuels, an abundance of gas and a shortage of liquid fuels.

You might also like...

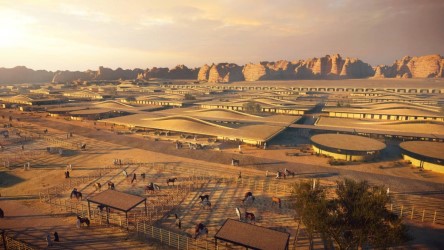

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

Jubail 4 and 6 bidders get more time

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.