People get surprised at the capabilities of artificial intelligence (AI), but today, the region’s heavier sectors are leaning on AI for the enhancement of everything from productivity to safety.

The GCC’s reliance on heavy industry, from steel and chemicals to ship-building and aerospace, goes back decades. And as oil-rich Gulf nations pursue economic diversification programmes, construction projects will only become more plentiful.

Consider the factors that are front of mind for a project foreman: resource management; asset tracking; health and safety; cheap and easy site surveys. These issues are the domain of smart construction – the application of AI to the building site.

More with less

The region is rapidly turning to AI as a means to do more with less. Digital transformation is a means to engage, empower, optimise and reinvent; and AI is the engine behind those improvements.

In October 2018, Microsoft surveyed more than 1,300 Middle East-based information technology (IT) decision-makers about their 2019 digital transformation plans. When asked about AI, almost two in five said their organisation had already adopted a solution using smart technologies, and more than one third (37 per cent) are planning to adopt in 2019.

Regional companies are also relaxing their AI budgets. Some 72 per cent will spend on AI this year; 34 per cent are setting aside more than 5 per cent of their budget and 9 per cent are investing more than 10 per cent of their budget.

Technologists have seen this change escalating across GCC industries over the past five years or so. Organisations, including contractors, have heard the success stories and are eager to join the parade.

While many factors have driven this adoption, the proliferation of data probably deserves most of the credit for making smart construction viable. The intelligent cloud can guzzle up mountains of workplace information and homogenise it, given the right IT stack. On construction sites, this means photos, logs of materials and equipment used, labour timesheets and even video footage are fodder for the intelligent cloud. So, the range of real-time capture scenarios available to decision-makers today is greater than ever, allowing deeper analysis of projects, leading to shrewder use of resources and greater profitability.

While many factors have driven this adoption, the proliferation of data probably deserves most of the credit for making smart construction viable. The intelligent cloud can guzzle up mountains of workplace information and homogenise it, given the right IT stack. On construction sites, this means photos, logs of materials and equipment used, labour timesheets and even video footage are fodder for the intelligent cloud. So, the range of real-time capture scenarios available to decision-makers today is greater than ever, allowing deeper analysis of projects, leading to shrewder use of resources and greater profitability.

AI opens the door to the kind of actionable insights previously hidden behind impenetrable complexity – analyses too timely or intricate for a human to undertake. Productivity, safety, quality and scheduling can all be enhanced through such deep dives.

Real-time field reporting through voice or text is child’s play. Based on keywords such as ‘delay’ or ‘safety’ within reports, the intelligent cloud can generate alerts for onsite or offsite stakeholders.

The cloud is also home to AI-driven smart-workflow systems that use optical character recognition technology to make engineering drawings easily searchable and allow those blueprints to be routed to the personnel that will need them, without the need for unnecessary human actions.

The internet of things (IoT) can support the use of wearable sensors to keep tabs on who is where onsite and what they are doing, generating further alerts in the event of distress or injury.

Other smart solutions allow unmanned aerial vehicles to map sites ahead of time and in real time, slashing survey costs, eliminating the need for many site visits and enhancing the assessments of project managers, as they add a level of detail often not captured by ground-based surveyors. Meanwhile, mixed-reality headsets can allow unprecedented collaboration between onsite and offsite personnel.

The autonomous vehicle is only a few years away, and while it may be many years before they are common on public roads, imminent widespread commercial use, especially on construction sites, seems assured. Caterpillar has, after all, already brought a range of autonomous dozers, drills and haulers to market for the mining sector. Robots capable of construction-

specific tasks are also on the way.

Perfect union

Meanwhile, the cloud oversees all, being capable of taking existing infrastructure, such as closed-circuit TV cameras, and infusing them with human-like intelligence. When fed real-time digital footage from a CCTV network, the intelligent cloud can analyse video with such nuance, it can augment your security and health and safety teams.

This is the perfect union of the intelligent cloud and the intelligent edge. The IoT, computer vision technology, machine learning, cognitive reasoning and advanced analytics come together with the chatbot to deliver the most advanced workplace safety.

Back-end AI can analyse video to spot fires, leaks, spills and non-compliance. Building sites have never been so efficient. This is the future of the construction industry – not replacing workers, but keeping them safe and enhancing their output.

About the author

Necip Ozyucel is cloud and enterprise business group leader at Microsoft Gulf

Necip Ozyucel is cloud and enterprise business group leader at Microsoft Gulf

You might also like...

UAE rides high on non-oil boom

26 April 2024

Qiddiya evaluates multipurpose stadium bids

26 April 2024

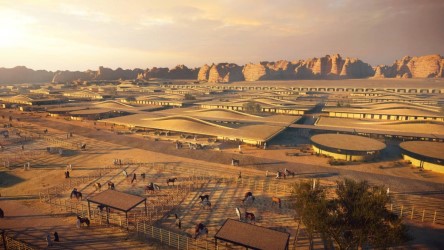

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.