State upstream operator Kuwait Oil Company (KOC) has prequalified three international contractors for a three-year contract to design, supply, operate and maintain a pilot water flood plant at Magwa near gathering centre (GC) 10 on the Marrat reservoir. Baker Hughesand Schlumberger, both of the US, and the UK's Wood Grouphave until 14 August to bid for the contract.

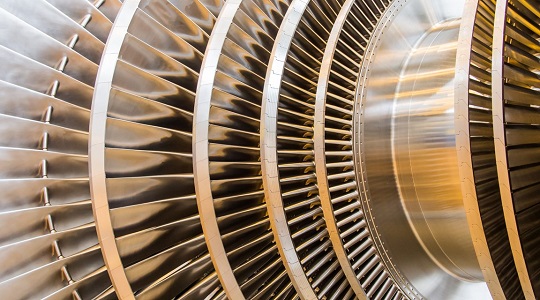

The scope of works calls for the design and construction of a variable-speed electro-submersible pump unit installed in the source well, a filtration plant, chemical injections skids for scale and oxygen corrosion control systems, as well as filtration aids, water transmission lines, storage vessels, instrumentation and control systems and auxiliary power generation units. Thepumpingfacilitywill have capacity to pump up to 10,000 barrels a day of water at various pressures. From the source well, the water will flow through a six-inch-diameter flowline to the injection well, where the choke in the water flowline will maintain the backpressure on the well and control the injection rate. The contractor has the option to purchase the facility at the end of the operation period. The water flood plant will inject water through wells into the oil zone. This will create a vertical flood front, forcing the crude in front of the water toward the production wells, thereby maintaining reservoir pressure and boosting oil production. If the scheme proves a success, KOC is likely to tender a similar, but larger project in future. A successful 5,000-b/d heavy crude pilot project carried out in 2002 by KOC with the technical assistance of the US' Parsons Engineering Corporationled to the issue earlier this summer of a tender for the installation and five-year operation of the 50,000-b/d early production facility (EPF - MEED 3:6:05).

You might also like...

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

Jubail 4 and 6 bidders get more time

26 April 2024

Amiral cogen eyes financial close

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.