Great wealth has put Saudi consumers a long way ahead of most of their Western counterparts in terms of purchasing power, but the world’s oil capital still lags behind Europe when it comes to logistics.

The kingdom’s transport infrastructure has not been upgraded fast enough to meet increased demand as consumer wealth has grown. In particular, capacity is needed at ports, and with almost no rail freight infrastructure, deliveries over the kingdom’s vast distances are left to third-party logistics operators who rely on trucking.

But the government is trying to redress the balance with projects such as King Abdullah Economic City (KAEC) in Riyadh, which will have a large logistics zone, including a deep-sea port with capacity for 10 million containers. The port is due to be completed by 2011. Jeddah Port has also not yet reached capacity.

Hussein Hachem, chief executive officer (CEO) of local logistics firm Aramex, says the government is investing excess revenues from the high price of oil wisely into roads and ports. “You only have to look at the $20bn KAEC project, upgrade to the port of Damman and the massive logistics project at Hail on the Red Sea Coast, north of Jeddah,” he says.

Hachem says the Saudi market has more than enough cargo to fill these projects and the region needs more capacity.

Boosting capacity

Third-party operators, multinational and local, are working to boost capacity. Many are investing heavily in warehousing and distribution networks in preparation for a change in the supply chain model, which has traditionally resulted in retailers and manufacturers operating in-house logistics divisions.

Just 12 per cent of logistics operations in the kingdom are outsourced. This compares with 20 per cent outsourcing in neighbouring Dubai and 80 per cent in Europe, according to Dan Wood, sales and marketing director, Middle East, at US-based DHL Exel Supply Chain.

Saudi Arabia’s gross domestic product (GDP) is about $400bn and the value of the logistics industry is almost 10 per cent of that figure, at nearly $20bn, according to Wood. Outsourced logistics or contract logistics is a substantial part of the market, worth about $4.9bn.

DHL Exel Supply Chain has an 8 per cent share of the Saudi contract logistics market and forecasts this will rise to about 10 per cent by 2012, worth about $127m.

Any third-party logistics operator serving the Middle East will say that the kingdom is the most significant market in the region, fuelled by the vast wealth of its 30 million-strong population. DHL Exel says there are huge opportunities in this relatively untapped logistics market. It recently completed marketing analysis identifying the most profitable sectors to focus on, says Wood. “We wanted to identify the key opportunities available to discover which sectors are growing at the fastest pace,” he adds. “We regard these to be oil and gas, consumer goods, aerospace and technology, in that order.”

International advantage

Oil and gas naturally looms large as the country’s major business sector. In fact, hydrocarbons accounted for 54.1 per cent of GDP in 2007. DHL Exel has handled the entire supply chain for Aramco, the world’s biggest oil company, for the past 18 months, including warehousing and distribution. Wood says contracts such as Aramco’s have been awarded to multinationals as local logistics companies cannot fulfil the entire supply chain in the same way. “They simply don’t offer the same warehousing and trucking options,” he argues.

His company provides warehousing, distribution and inventory management solutions and he says retailers in Saudi Arabia should review what they consider to be their core competency. “They should concentrate on sales and marketing of their products and leave the management of the supply chain to the experts like us.”

John Gould, CEO of local logistics firm KSA Agility, agrees that companies need to think about their key functions. “If a firm’s core business is selling laptops, for example, KSA can store them and deliver them as they require,” he says. “The Saudi outsourced logistics model will swing towards the European model in the next few years - from 20:80 in favour of in-sourcing to 80:20 in favour of outsourcing.”

“The current model means that our customers are our competitors - for example, our supermarket customers. It is not about coming up against fellow third-party logistics operators but we are encouraging our retail customers to rework their logistics and outsource to specialists like us.”

“It is about having a lean supply chain that has complete visibility from the manufacturer to the retail floor,” says Hachem. “While there is more in-house logistics provision, the trend is moving towards outsourcing.”

With this in mind, Hachem is developing his infrastructure in preparation. He says that Aramex, which specialises in moving fashion, IT/telecoms and consumer goods in Saudi Arabia, has a fleet of 200 trucks.

Regional network

Aramex connects the whole of the GCC using facilities in Dubai, Bahrain and Saudi Arabia. A Jeddah distribution centre is already operational and a facility opened in Damman in early June to complete the network. “Damman is a major gateway to the country, particularly for goods coming from the UAE,” says Hachem. “So we can bring sea freight into Damman and carry it out again using our trucking network. Bahrain is also just a half-hour drive away, and Kuwait and Qatar [are also nearby].”

DHL’s Wood says the current model of distribution is skewed by the high profit margins some products carry, which have sabotaged supply chains. For example, some distributors avoid carrying medicines that do not have a high profit margin and do not require regular restocking. “Distributors are incentivised by margins,” says Wood. “Some will only push those with a high margin.”

Wood sees great potential in the Saudi market and says DHL is looking to invest in KAEC. “We would like to get involved in the operating of the 67 square kilometre Logistics Zone,” he says. “This would follow on from the success of Transpark, [home to 500 factories] on the outskirts of Dubai.”

DHL is in negotiations over the site and would not elaborate on the subject.

The DHL Express arm of the business, which specialises in just-in-time delivery, is also pouring money into its Saudi network and is looking to spend up to $47m over the next two to four years. “We are building more express centres in Jeddah, Dahran and Riyadh as and when we win business,” says Dirk van Doorn, product and development manager at Middle East DHL. “We are also increasing our number of pick-up and drop-off points and the size of our vehicle fleet. Currently, our small caddy vans can handle up to 1 tonne, but the new vehicles will be able to handle freight up to 3 tonnes.”

DHL Express is also increasing the number of 40 foot trailers operational in Saudi Arabia, which is now a viable option following upgrades to major arterial roads. “The next investments should be on the inner-city roads,” says Van Doorn. “Most big businesses have a presence in the urban conurbation where congestion can be a real problem.”

Considered a local player, but global in every sense of the word, Agility refutes Wood’s claims that local players’ service levels cannot match up to the multinationals’.

Expansion plans

Gould says Saudi Arabia is very much at the forefront of his expansion plans, where the firm is building on an existing warehousing and distribution network.

“Outside of Kuwait, the largest investment we have made is in KSA,” he says. “We are the largest asset-based company in Saudi Arabia, investing $300m over the past five years. This equates to more than 2 million sq m of land. We own and operate more than 100 trucks through facilities in Jeddah, Damman and Riyadh.”

Agility has been in the kingdom for five years. “Through acquisition and our own set-up, we have expanded rapidly,” says Gould. “Our latest facility is a 40,000 sq m warehouse on the outskirts of Riyadh, which is scheduled to be finished next month. It will be the largest outsourced warehouse in Saudi Arabia.”

“It represents an investment of $60m. Half is temperature-controlled for pharmaceuticals, frozen food, fruit and vegetables, and the other half is air-conditioned for high-value products. When it is 40 degrees outside, it will be minus 25 degrees in the coolest part of the facility.”

Agility is merely catering to the needs of a fast-growing population, with increasing tastes for Western foods served in the big chain restaurants, he says.

In the Middle East, nothing is ever the biggest for very long. Agility is also constructing a 1 million sq m facility in Jeddah. Like the Riyadh centre, it will be half-chilled and half-air conditioned. It is set for completion in two years.

“We can store products until restaurant and supermarkets need them,” says Gould. “Before they would have been doing this themselves but they are slowly moving towards outsourcing. A lot of factories have been set up to serve the local market and they need warehousing and distribution services.”

There are also plans for a similar facility in Damman of about 400,000 sq m, but construction will not begin for a few years.

While the credit crunch has depressed infrastructure spending in the West, the Middle East remains unchanged.

Business and trade is booming, and growth in demand is outpacing capacity, particularly for sea freight, but infrastructure projects are numerous and the Saudi government is working hard to ensure additional capacity is completed soon.

You might also like...

Ajban financial close expected by third quarter

23 April 2024

TotalEnergies awards Marsa LNG contracts

23 April 2024

Neom tenders Oxagon health centre contract

23 April 2024

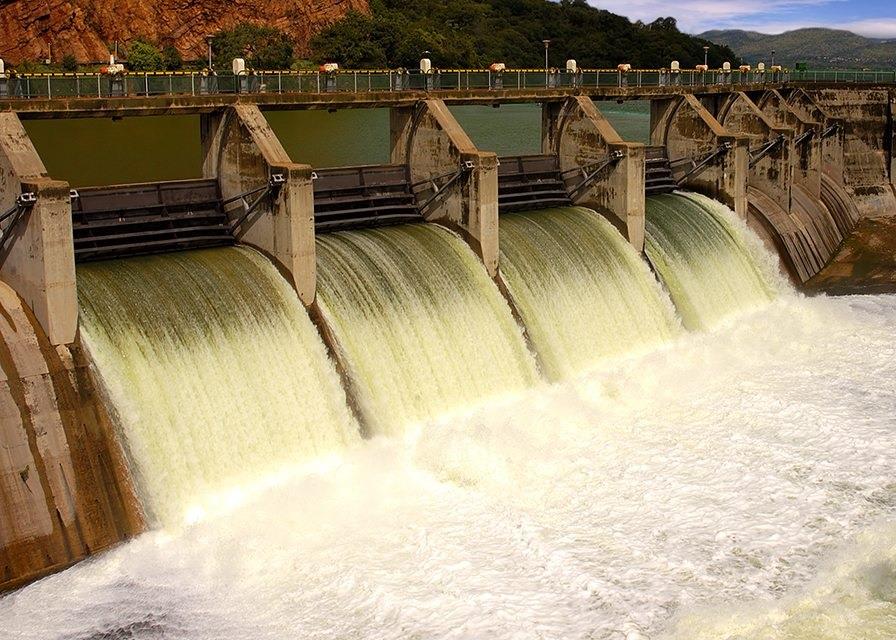

Neom hydro project moves to prequalification

23 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.