Technology that allows for much smaller plants is being developed

Until recently, if a company was thinking of building a gas-to-liquids (GTL) plant it meant one thing above all else: scale. The plants were physically large, needed copious amounts of gas feedstock and demanded big investments.

The Oryx plant in Qatar, a joint venture of Qatar Petroleum (QP) and South Africas Sasol, uses 330 million cubic feet a day (cf/d) of natural gas to produce 34,000 barrels a day (b/d) of diesel, naphtha and liquefied petroleum gas. The nearby Pearl project, a joint venture of Shell and QP, is even bigger. It uses 1.6 billion cf/d of gas to make 260,000 b/d of diesel and other products.

Small-scale plants

There are not many places with enough gas to allow for refineries of this size. South Africa and Malaysia are among the few other countries to have GTL plants, although new ones have been mooted for the US, Canada, Uzbekistan and Nigeria. But several companies are developing technology that is opening up the market at the other end of the scale. By using new techniques, they are able to develop plants that use much smaller volumes of gas. That means they can be deployed in hard-to-reach locations and exploit gas that is currently flared, reinjected into oil fields or left in the ground. And with a startup cost of about $200m, they are a small fraction of the almost $20bn that Shells Pearl GTL cost to develop.

I compare [the market] to the space programme: its only open to a very small number of players because of the price tag

Roy Lipski, Velocys

What Shell and Sasol do are very large plants, and theyre increasingly aiming to do larger and larger plants, says Roy Lipski, chief executive officer (CEO) of London-listed Velocys, one of the new band of companies. Thats a niche market. I compare it to the space programme: its only open to a very small number of players because of the price tag. And there are only a few locations on earth where you can secure enough gas. What were trying to do is provide GTL for the mainstream of the industry. The scale we are targeting is 1,500-15,000 b/d of production, which requires 15-150 million cf/d of gas.

His space analogy is an apt one. Some of the technology that Velocys uses was developed at the Pacific Northwest National Laboratory for the US space programme. The scientists were trying to develop technology that could produce oxygen and fuel from resources found on Mars or the Moon. That required small, light chemical reactors that could be easily transported. The micro-channel process reactor they developed lies at the heart of what Velocys now does.

Not everything is so novel though. Velocys uses the same Fischer-Tropsch process, designed by German scientists in the 1920s that is also used by Shell and Sasol. This involves taking natural gas and splitting it into hydrogen and carbon monoxide. This synthesis gas (syngas) is then reassembled via the Fischer-Tropsch process into different length hydrocarbons to produce synthetic crude or syncrude, which can be further refined into diesel and other products.

With its micro-channel reactor, Velocys can do all this on a far smaller scale than happens at Oryx or Pearl. In addition, its plants are modularised so they can be built in prefabricated pieces and then transported and assembled at the site where the gas is located. The technology is already being deployed in the US, where the local Pinto Energy is developing a GTL plant in Ohio. Its 2,800-b/d facility will convert natural gas from nearby shale reserves into fuel, solvents, lubricants and waxes, using Velocys technology. The plant is being built by the US Ventech Engineers International in Texas before being transported to Ohio for installation and should start up in early 2016.

Interested customers

Lipski says his company has at least 10 other requests from customers at various stages of development or evaluation, including from Calumet Specialty Products and Red Rock Biofuels in the US and British Airways in the UK. It has also built a demonstration plant for Brazilian national oil company Petrobras in the northeast of Brazil.

The vast natural gas resources in the Middle East make it a natural long-term target for us

Robert Johnsen, Primus Green Energy

But Velocys does not have this market all to itself. Other companies such as CompactGTL in the UK and Synfuels International and Primus Green Energy in the US are moving ahead with their technology. CompactGTL has also run a commercial demonstration plant for Petrobras. The plant was built in 2010 in Aracaju to process gas from offshore fields. Petrobras gave approval to the technology the following year. Like its rival, CompactGTL is targeting the part of the market that the super-majors have ignored.

The whole basis of Shell and Sasol is economies of scale. We can build smaller plants and modularise them, but the basic chemistry is the same, says Peter Riches, CEO of CompactGTL. We target plants under 10,000 b/d of liquid production. Our plants are half the size or smaller than those of Shell and Sasol.

In October this year, Primus Green Energy also started up a demonstration plant at its New Jersey headquarters. The plant can produce 100,000 gallons (2,380 barrels) of gasoline a year and diesel and jet fuel lines are due to be added in 2014. Its CEO, Robert Johnsen, says it also expects to break ground on its first commercial plant next year, which will produce 25 million gallons (595,000 barrels) a year of gasoline, equivalent to just over 1,600 b/d.

Cost-effective process

Primus Green Energy uses a different chemical process to most others in the market. Instead of Fischer-Tropsch, it uses STG+, which stands for syngas-to-gasoline. This is an evolution of technology known as methanol-to-gasoline (MTG) developed in the US in the 1980s, which converts syngas into liquid methanol and then into gasoline. That technology did not take off, however, and few MTG plants have been built. The first was in New Zealand and ran from 1985-97.

The STG+ process converts syngas directly into gasoline, avoiding the methanol stage, and Johnsen says it offers an advantage over competing systems. STG+ is so efficient that it is cost effective at scales as small as 400 b/d, which opens up an entirely new market for alternative fuel technologies, he says.

Synfuels International has also developed a new process, first converting gas to acetylene, then to ethylene and finally to gasoline. It too has a small demonstration plant, in Texas.

Their individual plants may be relatively small, but the potential market for these new GTL companies is not. Because of their size and relatively low costs, the plants can be deployed in places where, until now, no one has been able to exploit the gas, whether onshore or offshore. We think theres enough low-value feedstock in the size ranges we are targeting to make as much as 25 million b/d of fuel, says Lipski.

If correct, that would be almost equivalent to the total oil production of the entire Middle East, which stood at 28 million b/d last year, according to UK oil major BP.

While they wait for the market to take off, two of the firms are already in dispute, however. Velocys claims that CompactGTL is infringing some of its patents, a claim that Riches says his company utterly and completely refutes. Unless a compromise can be struck, Lipski says, the case should reach the High Court in London in July next year.

In the meantime, the firms are all competing for customers. The potential buyers of the technology range from small and medium-sized oil companies to refinery operators and independent project developers. To date, the greatest interest has been shown in the Americas, not least because of the shale boom in the US and the discovery of extremely deep offshore oil fields in Brazilian waters. But there should be opportunities in parts of Asia, Africa and the Middle East too.

The most noise and publicity is in the Americas, says Riches. But the former Soviet Union has a big problem with flared gas and you can go to a lot of parts of the Far East and Australia.

In terms of flaring, the worst offender is Russia, which burnt off 37.4 billion cubic metres of gas in 2011, according to the US National Oceanic & Atmospheric Administration. It was followed by Nigeria with 14.6 billion cubic metres, Iran at 11.4 billion cubic metres and Iraq at 9.4 billion cubic metres. However, opinion is divided on how promising the opportunities might be in the Middle East.

Generally speaking, many parts of the Middle East are gas poor, says Lipski. The consequence is that the opportunities for GTL are specific and niche. Having said that, I do believe there is a promising future all over the world for biomass-to-liquids, the ability to turn municipal, agricultural and household waste into usable fuels.

Regional opportunities

Johnsen is more optimistic, although the ownership structure of his company may make it difficult to do business in some countries in the region.

The vast natural gas resources in the Middle East make it a natural long-term target for us, he says. Israel, for instance, which is the home of our primary investor IC Green, once had next to no domestic energy resources, but the recent discovery of offshore natural gas reserves that are far larger than previously believed is a game-changer for the economy. We could build small-scale plants for use at oil fields in the Middle East where hundreds of millions of dollars worth of associated natural gas are now being flared.

For its part, Synfuels International has licensed exclusive marketing rights for its technology in the Middle East and North Africa, the former Soviet Union and the Indian subcontinent to Kuwaits Aref Energy.

Only after the technology these companies offer has been rolled out on a larger scale will it become clear how viable their plans are; introducing new technology into a market is rarely straightforward. For Shell and Sasol at least, the gas volumes they are targeting means they do not represent a threat to the biggest GTL operators.

You might also like...

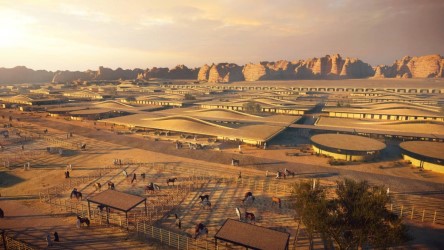

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

Jubail 4 and 6 bidders get more time

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.