The Royal Dutch/Shell Group's senior management were in the public gaze in early 2004. An unexpected reserves downgrade, followed by the departure of the chairman, ensured the supermajor's place in the spotlight. So when Malcolm Brinded stood up to give his keynote address at the Finance & Investment Qatar Conference in London in early March, it was no surprise that the chief executive for Shell Exploration & Production and Shell Gas & Power expressed pleasure, as well as some relief, at being given the opportunity to present a landmark project, rather than the latest twists and turns in the reserves saga.

London conference, just days after former chairman Phillip Watts had resigned, underlined the importance Shell attaches to its gas-to-liquids (GTL) venture in Qatar. With a price tag of up to $5,000 million, the world's largest GTL project is a major undertaking - even by Shell standards. It fits into the company's stated aim of moving 'more upstream and profitable downstream'. And it marks the company's re-entry to Qatar after an absence of more than a decade. The scheme, known as Pearl GTL, will be the first integrated GTL project in Qatar and the first to be implemented according to a development and production sharing agreement (DPSA), which was signed on 8 July. Under the programme, to be 100 per cent financed by Shell, two wellhead platforms will be installed in a dedicated North field block to deliver 1,600 million cubic feet a day (cf/d) of gas, via two 28-inch-diameter pipelines, to Ras Laffan. Here, it will be processed in a new gas treatment plant - similar to the Dolphin facility now being built - with the lean gas being dispatched to a two-train GTL plant. On completion of the second train in 2011, the plant will produce about 140,000 barrels a day (b/d) of GTL products, as well as more than 200,000 b/d of liquids. The Pearl GTL plant will draw extensively on Shell's experience with its Bintulu plant in Malaysia. In commercial operation since 1993, the 14,700-b/d plant has been the test-bed for Shell's GTL ambitions, enabling the company to develop its proprietary Shell middle distillate synthesis (SMDS) technology and catalysts and gain an invaluable insight into the operation and performance of a GTL complex. The strides made are evident in the fact that after initial problems, including an explosion in an air separation unit in 1997, performance levels at Bintulu have exceeded 99 per cent over the past two years. The size of the Pearl GTL trains - each of 70,000 b/d - is considerably larger than Bintulu. However, Shell maintains that on a modular basis, the upscaling required for Ras Laffan will be relatively modest. The air separation units - four to serve each Pearl train - will be 13 per cent bigger than Bintulu's, the synthesis units will be scaled up by 12 per cent, and the gasification facilities will be 3.5 times larger. The unit costs of building the Ras Laffan plant will be considerably lower than those achieved at Bintulu. Just as the LNG market has benefited over the past 15 years from sharply reduced capital costs through bigger trains and better economies of scale, so has the GTL sector. The initial capital costs on Bintulu were in the range of $50,000 per b/d of capacity. On Ras Laffan, Shell is talking of below $20,000 a b/d, a figure it widely expects to reduce further, especially on brownfield expansions. By any standards, the Pearl GTL project will be a major logistical undertaking. The onshore construction works alone will require 2,300 equipment items, weighing 100,000 tonnes, 50,000 tonnes of piping, 30,000 tonnes of structural steel, 200,000 cubic metres of concrete and 1,800 kilometres of cable. At the construction peak, 25 cargo ships a month will be required to serve the project. Construction will also take place at a time of frenetic activity at Ras Laffan. Although the Dol

You might also like...

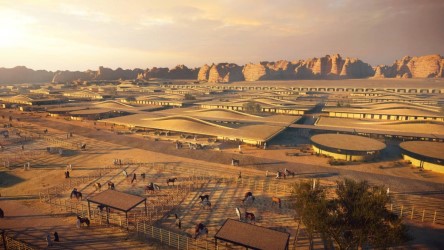

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

Jubail 4 and 6 bidders get more time

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.