Positive impact on the bottom line

Why did Shell choose to invest in gas-to-liquids (GTL) in Qatar?

Applying technology on this huge scale and investing so heavily in a single project does not happen everywhere in the world; it needs an enabling environment, and that enabling environment exists in Qatar. Not only is the country blessed with abundant gas resources, but it also possesses the leadership, decision-making and drive to deliver transparency in business dealings.

For Shells partner in the Pearl GTL, the State of Qatar, GTL technology has allowed for diversification, transforming decades worth of gas reserves into economic progress by opening up new markets and opportunities.

The financial rationale behind GTL projects is often questioned. What made Qatar a viable place to invest?

In addition to the above points, Qatar Petroleum acts as a real partner. There is a fundamental belief that working together for mutual success is the right approach.

For how long has the Pearl GTL been producing, and with what output?

Pearl GTL started up in March 2011 and the first shipment of gasoil was achieved in June of the same year. The project then produced a commercial cargo of naphtha in August and high-quality base oil in October 2011. The first cargo of normal paraffin, a chemical feedstock, was lifted in March 2012. In December 2012, the first GTL jet fuel shipment a blend of GTL kerosene and conventional jet fuel was loaded at Ras Laffan. Pearl achieved full production at 90 per cent or higher on both trains at the end of 2012, marking the completion of the ramp-up for this flagship project.

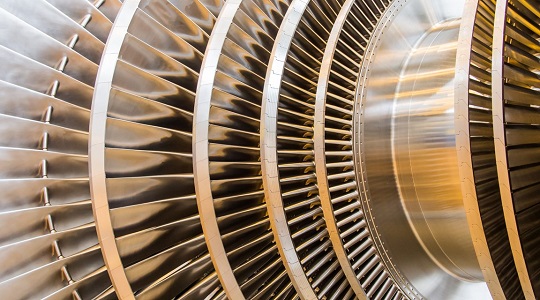

Developing a GTL project requires technical mastery, upstream-downstream integration and financial strength

Neil Gilmour, Shell Integrated Gas

The dimensions of Pearl GTL are truly staggering. The project covers an area of 250 hectares, and it took more than 500 million man-hours to design and build. At its peak, more than 52,000 workers were involved in the facilitys construction. Some 2 million tonnes of freight were shipped and imported via a dedicated berth constructed by the project at Ras Laffan port.

What is the product split?

Pearl GTL converts up to 1.6 billion cubic feet a day of wellhead gas from 22 offshore wells in Qatars huge North Field using Shells proprietary middle distillate synthesis process.

From this, a range of high-performing GTL products is created: gasoil to be used as diesel fuel; kerosene to be used as jet fuel; base oil to be used for high-quality lubricants; and naphtha and normal paraffin for the petrochemicals industry.

What price is Shell paying for Qatari gas?

The details of the agreement are commercially sensitive and cannot be shared under the terms and conditions of the development and production-sharing agreement between Shell and the State of Qatar.

Where are the different products from the plant marketed?

Products are shipped to customers across the world; for example, gasoil is exported to Europe, naphtha and normal paraffin to East Asia and base oils to the US, Europe and China.

Is the project profitable?

Pearl GTL is making a positive impact on our bottom line and recovering our sunk costs.

What are the prospects for the development of the global GTL market in the future?

GTL creates an additional route to monetise a countrys natural gas resources by turning gas into high-quality liquid fuels and products. And with recent advances unlocking vast new supplies of natural gas across the globe, we see more and more opportunities for GTL. It is therefore not surprising that the GTL industry as a whole continues to develop an impressive portfolio of projects, at different sizes and stages of maturity.

However, developing a GTL project is no simple feat and requires technical mastery, upstream-downstream integration and financial strength. Shell is uniquely positioned to make it a success given our commercial capability, our in-house GTL technology (the culmination of four decades of research, development and commercial deployment), and our proven ability to successfully deliver integrated megaprojects.

Which areas of the world are likely to show the greatest GTL demand?

In many ways, GTL can be seen as complementary to traditional gas commercialisation routes for a country with abundant, affordable gas resources. It serves a very different set of markets and customers, with different price and demand dynamics and product logistics chains.

Is there a sufficiently strong financial rationale for the development of further GTL projects?

Shells GTL capabilities unlock value from natural gas by converting it into valuable, high-quality liquid hydrocarbon products. This creates an additional route to monetise a countrys natural gas resources and offers the full upside of accessing the oil markets. The long-term price of natural gas relative to that of oil is an important consideration. As such, it is potentially a valuable strategic diversification process for a country with abundant, affordable gas resources. Also, lets not forget that the GTL industry is relatively young and that process and product innovation continues, offering favourable prospects for long-term partnerships.

What are the risks involved with investing in GTL?

For Shell, this question is not about GTL technology, which we have sufficiently de-risked over the past 40 years. That said, applying GTL technology at a world scale as we have done, and investing so heavily in a project, does not happen everywhere in the world. It needs an enabling environment: collaborative partners and, of course, abundant gas resources.

Shell strongly believes in the value of a comprehensively integrated approach to GTL projects. In our definition, this includes upstream production and development as well as downstream product marketing next to the GTL process itself. It equally includes consideration of technical, organisational, commercial, economic and political dimensions and, of course, extends to partners, contractors, local communities and other external stakeholders.

How does Shells GTL process work?

At Shell, we are actively mastering GTL technology at all stages from the nanometre scale right through the products that are used around the world.

The GTL process consists of three stages. In the first stage gasification synthesis gas (syngas), a mixture of hydrogen and carbon monoxide, is manufactured from natural gas by partial oxidation. Impurities are removed from the syngas.

Shells gasification process offers advantages in terms of selectivity, conversion level and thermal efficiency and provides a good fit with the Shell synthesis process.

A second stage, known as Fischer-Tropsch synthesis, converts the syngas into liquid hydrocarbons using a catalyst. In this stage, a liquid is formed that looks and feels like wax at room temperature. Shell employs the Shell heavy paraffin synthesis process at this stage. This process uses a multi-tubular, fixed-bed technology that can easily be scaled. It gives a reliable separation between products and the catalyst, as well as a heavier product slate, which leads to better product properties.

The final stage is hydrocracking and isomerisation, which cuts the molecule chains into shorter lengths. This yields high-quality liquids such as diesel, kerosene and lubricant oil.

Shells heavy paraffin conversion technology has been specifically developed for the unique properties of Fischer-Tropsch distillates and offers better yields, selectivity and flexibility than a standard refinery hydrocracking process. Shell HPC [heavy paraffin conversion] delivers a heavier (more valuable) product slate and allows for the production of high-quality base oils.

What advantages does GTL have compared with conventional refined products?

The first advantage of Shells GTL products is that we are increasing the overall supply of highly demanded liquid hydrocarbons. We are also increasing security of supply as Pearl GTL is the worlds largest source of high-quality GTL products.

Each GTL product has specific advantages. For example, Shells GTL gasoil, when used in automotive applications such as buses, can help improve local air quality by reducing emissions such as soot (particulates), when compared with conventional diesel fuel. When you consider heavily congested cities, we believe the benefits speak for themselves.

The market does not differentiate between GTL and other refined products. Is it possible that there will be such differentiation in the future?

Lets be clear: what matters most to customers is the performance of the final product and its benefits, not how products are presented or differentiated in the marketplace. For instance, GTL base oils have a number of advantages over traditional base oils. These include a better viscosity index, better low-temperature flow properties, better volatility and better oxidation stability.

In other words, products formulated with Shell GTL base oils deliver less engine wear, better fuel economy, reduced motor oil consumption and longer service intervals, and therefore longer engine oil life.

Simply put, our GTL products allow us to offer more products to the market as a whole and give Shell customers more product choice.

Is Shell considering GTL projects elsewhere?

We recently announced that we are exploring the possibility of building a 140,000 barrel-a-day GTL facility on the US Gulf Coast. After much analysis, we have selected a site in Ascension Parish, near Sorrento, Louisiana, for this potential project. While an important step, we still have a great deal of additional work to do before deciding whether or not to build the proposed Gulf Coast GTL project. A decision is still years away.

We use our experience, scale and innovation to offer resource holders sustainable integrated gas monetisation routes, for example, Prelude FLNG, the worlds first floating liquefied natural gas facility, to be located off the coast of Australia, and of course Pearl GTL, the worlds largest GTL plant, located in Qatar. We offer more choices than ever before and GTL is an integral part of our portfolio.

Pearl GTL construction timeline

2002 Statement of intent between Shell and government of Qatar signed

2003 Heads of agreement signed; seismic studies completed

2004 Development and production-sharing agreement (DPSA) signed; appraisal wells drilled

2005 Front-end engineering design completed; permit to construct granted; project management contractor appointed; all EPC contracts tendered; synthesis reactors ordered; development drilling contract awarded

2006 Final investment decision; catalyst production begins; EPC contracts awarded; site preparation works and procurement commence

2007 Construction of plant and offshore platforms begins

2010 Well drilling completed. Completion of first train

2011 First gas flowing from wells; first sale of condensate and GTL product; start of DPSA; official inauguration

2012 Second train completed

EPC=Engineering, procurement and construction. Source: MEED

You might also like...

Amiral cogen eyes financial close

26 April 2024

Lunate acquires 40% stake in Adnoc Oil Pipelines

26 April 2024

Saudi Arabia's Rawabi Holding raises SR1.2bn in sukuk

26 April 2024

Iraq oil project reaches 70% completion

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.