State-owned oil company Qatar Petroleum eyeing investment opportunities that could use more feedstock

Qatar Petroleum has not ruled out further world-scale investments in its petrochemicals business unit, despite having two megaprojects under development.

Speaking at the MEED Qatar Projects 2014 conference Mohamed Nasser al-Hajri, director of Downstream Ventures for QP, stated that while the company did not have a specific scheme in mind it was always open to new opportunities.

Al-Karaana and Al-Sejeel will almost double our capacity in ethylene and polyolefins, Al-Hajri said. However, we will always look for further schemes that can utilise ethane and natural gas liquids.

Doha has previously stated that it plans to produce 23 million tonnes a year of petrochemicals by 2020.

The Al-Karaana petrochemicals project is a joint venture of QP and the UK/Dutch Shell Group and is at the engineering, procurement and construction (EPC) tender phase. The scope includes a mixed-feed steam cracker unit that will be supplied with ethane and propane feedstock. The cracker will have a capacity of 1.1 million tonnes a year (t/y) of ethylene and 170,000 t/y of propylene.

A further three units will produce linear alpha olefins (LAO), monoethylene glycol (MEG) and oxo-alcohols.

The MEG unit will have a capacity of 1.5 million t/y and will use Shell Group technology. The work involves the construction of two trains, each with a capacity of 750,000 t/y.

The LAO and oxo-alcohols units will have capacities of 300,000 t/y and 250,000 t/y respectively.

The Al-Sejeel petrochemicals project is a joint venture of QP and Qatar Petrochemicals Company (Qapco) and is at the front-end engineering and design (feed) phase.

The scheme will produce 1.4 million t/y of ethylene when completed, which will feed other units at the proposed complex. A further 850,000 t/y of high-density polyethylene (HDPE), 430,000 t/y of linear low-density polyethylene (LDPE), 760,000 t/y of polypropylene and 83,000 t/y of butadiene will be produced.

It will also include an aromatics unit sourcing naphtha from the Ras Laffan Condensate Refinery and produce 1 million t/y of paraxylene, 500,000 t/y of benzene, 1 million t/y of purified terephtalic acid (PTA) and 650,000 t/y of polyethylene terephthalate (PET).

The projects are fully expected to be fully commissioned in 2018 and 2019 respectively.

More from MEEDs Qatar Projects 2014 conference

You might also like...

UAE rides high on non-oil boom

26 April 2024

Qiddiya evaluates multipurpose stadium bids

26 April 2024

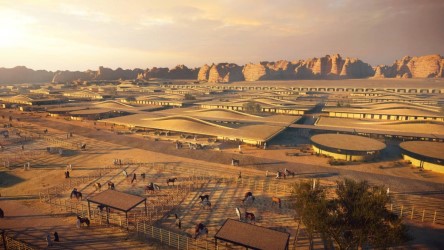

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.