Governments across the region are delaying plans to build additional refining capacity.

There may be a clear need for governments in the Middle East and North Africa to develop more downstream facilities, but the future of many refinery projects is in doubt because of a combination of a crumbling global market for oil and refined products, a lack of financing and increasingly unsteady foreign partners.

For oil-rich states, extending refinery capacity has been on the agenda for some time as a way to boost revenues and create new local industries. Refineries do not come cheap, however, and even less so when they are attached to major petrochemicals complexes that allow producers to expand their range of products.

Project costs soared alongside rapid economic growth in 2007 and 2008, with schemes such as Saudi Aramco’s Jubail and Yanbu refineries, which were originally projected to cost $5-6bn each, doubling in price to more than $12bn.

Declining margins

In 2009, however, a collapse in demand and falling prices for both crude oil and refined products has dented the potential profitability of such giant projects.

Yet industry analysts say that despite the adverse conditions of recent months, building new refineries in the region still makes sense in the long term, especially if oil-dependent states are to successfully diversify their economies.

According to one London-based oil analyst, it will also solve an issue that has troubled many oil producers for years: the need to import downstream products because of the lack of refining capacity in the region.

“At the moment, they sell crude and more or less import it back in product form,” says the analyst. “It does not make sense. You can make a lot of money from exporting crude oil, but you still need things like gasoline for cars and naphtha to make petrochemicals.”

The analyst says regional producers should be able to make a profit on refined products in almost any given scenario for oil prices, as Middle East refiners are largely part of national oil companies (NOCs), which have direct access to crude oil.

According to UK energy giant BP, the Middle East is the world’s largest exporting region for crude oil. In its Statistical Review of World Energy report in 2008, it says the region refined an average of 6.3 million barrels a day (b/d) of crude oil in 2007, and exported an additional 17 million b/d. However, on average the region also imported 200,000 b/d of refined products during the year.

At the time, refining margins - the profit made from the products sold after processing a barrel of crude oil - reached a record average level of $9.40 a barrel.

Although they have since declined, those profit margins encouraged Middle East producers to press ahead with their plans to develop new refinery projects, to the extent that many analysts predicted the region would push the world into overcapacity in the next decade. As recently as September 2008, Iran announced a spending programme of $22bn to add 1.5 million b/d of new refining capacity over the next four years.

Despite the plans to build refineries across the region, only $9.7bn worth of engineering, procurement and construction (EPC) contracts for refining projects were awarded in 2008, according to Gulf project tracker MEED Projects. Of these, only $600m worth are moving ahead.

Saudi firm Contracting & Construction Enterprises was awarded a $300m contract for early work on the 400,000-b/d Jubail export refinery planned by Saudi Aramco and France’s Total in December 2008. A $314m contract was also awarded to South Korea’s Samsung Engineering for the construction of a 400,000-tonne-a-year (t/y) lube oil refinery for Bahrain Base Oil Company in August 2008.

Elsewhere, projects are suffering from a series of delays or are struggling to get off the ground at all. In August 2008, Egyptian finance house Citadel Capital was forced to delay progress on its $2-3bn refinery project with Egyptian Refining Company. Three months later, in November, Oman’s Oil & Gas Ministry put its 300,000-t/y refinery at Duqm, valued at $5bn, on hold because of difficulties in raising the necessary finance.

Abu Dhabi’s International Petroleum Investment Company (Ipic) also shelved its $1.5bn Fujairah refinery in January 2009, saying it no longer saw the project as a priority.

Saudi Arabia was also hit in late 2008, with two of the biggest projects in the kingdom delayed while the plans are reviewed. Bidding has been put back on the Saudi Aramco/Total joint venture refinery at Jubail, and the bidding process has been frozen on Aramco’s joint venture with ChevronPhillips for a refinery of the same 400,000 b/d size at Yanbu.

Many local contractors in the kingdom say the projects have not been put on hold indefinitely, but Saudi Aramco is trying to take advantage of commodity prices coming down to reduce the cost of the schemes. Aramco has already been successful in doing this on other oil and gas projects, such as the Karan scheme, where the company cut the cost of EPC contracts by more than $100m to $1.2bn. A total $1.2bn cut in the cost of the Jubail refinery is now believed to be a target.

Industry analysts say that major projects planned by Aramco are more likely to face difficulties because of the international partners involved, rather than any change in approach by the Saudi energy giant.

“We have not seen anyone backing away from the projects that are physically under way yet, [and] I don’t think we have seen a slackening of desire going forward either,” says Roger Green, Middle East analyst at US consultant Nexant. “Getting investment is difficult and the current climate will weigh more heavily on [international] industry partners in the investment, especially if they are private equity backed.”

“Some of these [foreign] companies have shareholders and need to justify this,” agrees John Sfakianakis, chief economist at Saudi bank Sabb. “Aramco is certain that it needs to push ahead on the refineries, but it needs foreign partners. It has a huge cash pool and a lot of other foreign companies are not sitting on these kinds of reserves, so they will have to take a wait-and-see stance on the global economy.”

However, some projects that are already under way or nearing completion, such as PetroRabigh’s $10bn-plus integrated refinery and petrochemicals complex at Rabigh, are likely to suffer because of the financial crisis.

PetroRabigh, a joint venture of Saudi Aramco and Japan’s Sumitomo Corporation, made a loss of $355m in 2008, despite having started up its refining capacity in the fourth quarter of the year. At the time, the company said the loss had been due to a downturn in demand and a delay in the start of its commercial operations.

The complex is now 70-80 per cent complete, according to one source close to the project, with full production capacity expected to be in place by the third quarter of 2009.

Domestic politics can be a further complication for Middle East refinery projects, and nowhere more so than in Kuwait. Of the $9.6bn worth of EPC contracts awarded in 2008, $9bn were for packages on Kuwait National Petroleum Company’s (KNPC) planned refinery at Al-Zour.

The winners were a Japanese/South Korean joint venture of JGC Corporation and GS Engineering & Construction; three other South Korean firms, Daelim Industrial Company, SK Engineering & Construction and Hyundai Engineering & Construction Company; and the US’ Fluor Corporation.

Although the winners were announced in April 2008, a parliamentary debate over the way the contracts were awarded has led to the them being put on hold. The related Clean Fuels Project to upgrade the Mina al-Ahmadi and Mina Abdulla refineries is also on hold as it has become embroiled in the debate over how KNPC awards contracts.

Local contractors now say the political situation has become so intense that there is little hope for contract awards moving ahead on either project in the near future. “There will be no progress,” says one Kuwait-based oil analyst.

With a parliamentary committee investigating the way the contracts were awarded, a source at another international oil company in the country agrees. “I don’t think anything is going to happen very soon,” he says.

Work on Algeria’s Sonatrach Tiaret refinery project is also believed to have been held up by a combination of political and financial issues.

In Egypt, Egyptian Kuwaiti Holding Company abandoned plans to develop a $2.2bn refinery and petrochemicals plant at Ain al-Sokhna after the government levied a 20 per cent tax on companies operating in the country’s free zones.

Meanwhile, in Iraq, the gap between the government’s ambitions and the need for international oil majors to turn a profit could lead to difficulties as the country looks to make the most of its large reserves by developing a series of new refineries.

Unattractive terms

The London-based oil analyst says Middle East governments need to think about the long term when it comes to the planned projects, regardless of short-term issues such as prices being relatively low.

“It makes sense in a recession,” he says. “This is good time to sort out infrastructure, to get it built for when the economy reverts back to normal.”

Nexant’s Green says that all Middle East national oil companies are in a relatively strong position at the moment, while their private sector competitors in the West are under increasing pressure.

“I think we will see some shake-out of balance in Europe and the US [in the coming years],” he says of both the refining and downstream petrochemicals industry, adding that development into downstream markets will also help provide a stronger industrial base for Middle East economies.

You might also like...

Qiddiya evaluates multipurpose stadium bids

26 April 2024

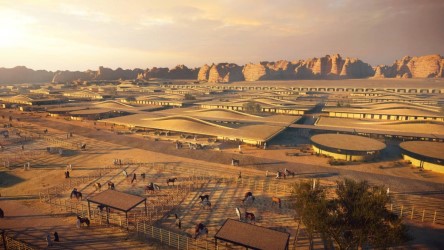

Al Ula seeks equestrian village interest

26 April 2024

Morocco seeks firms for 400MW wind schemes

26 April 2024

Countries sign Iraq to Europe road agreement

26 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.