Q. Why is digital transformation so important for industrial customers?

Q. Why is digital transformation so important for industrial customers?

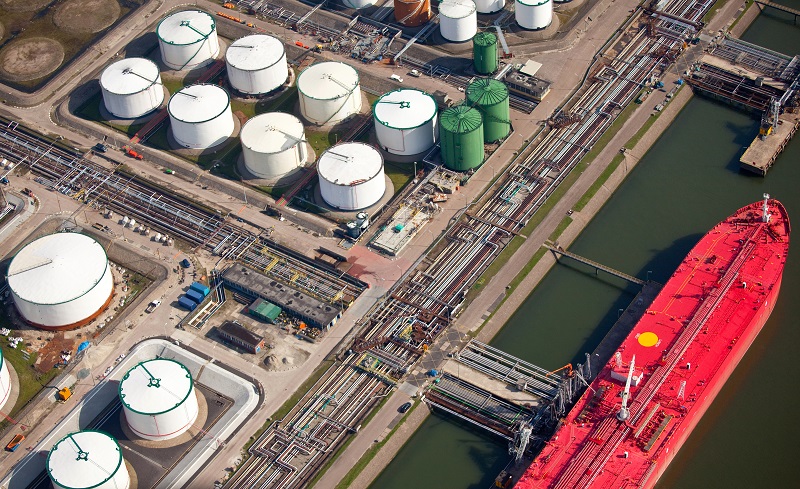

The productivity and efficiency of industrial processes can be seen in terms of cause and effect, requiring investment to meet key performance indicators. In the Middle East and North Africa (Mena) region, this is particularly important since industrial environments such as oil and gas involve high capital expenditure. Digital transformation and real-time process optimisation ensure the highest-possible efficiencies for existing equipment, without adding much to investment costs. Tools to monitor, interpret and analyse in real-time are key. Digitisation has already had a positive impact in the Mena region, especially in sectors such as banking and retail. However, there is still a massive opportunity in industrial sectors.

Aveva’s powerful portfolio makes it the first company in the engineering and industrial software market to comprehensively address the end-to-end digital transformation imperatives with an integrated portfolio of solutions that deliver efficiency, unlock value and empower people across the lifecycle of capital assets and operational value chains.

Q. What are the key technology trends in the region?

Much of the technology adoption in the region is focused on gaining precise insights and having the ability to make informed, data-driven decisions validated by specific simulations and models. Ultimately, this is about large industrial operations gaining the ability to be agile. Based on first principle simulation, process optimisation modelling allows businesses to anticipate opportunities and be nimble enough to leverage opportunities for profit – whether through anticipatory procurement, predictive maintenance or evaluating process changes before they are deployed. Predictability and transparency are the core requirements for regional industry, and trends centre on accurate monitoring, cogent real-time analysis and comprehensive process modelling.

Horizontal capabilities such as big data, cloud and industrial internet of things (IoT) are being deployed at scale in both midstream and downstream industries – for example, using data collected across hundreds of thousands of data points in an operational facility, and providing visualisation in an operational way. Another great example of disruption is applying machine learning to predict unplanned downtime.

Q. How is Aveva contributing to the region’s digital transformation journey?

Aveva offers solutions that optimise the entire process model lifecycle – from design to decommissioning. Our solutions can map, model, monitor and control every aspect of a project workflow, from industrial processes to schedules and collaborations. We have been cognisant of the fact that to be effective in the real world, our solutions need to integrate enterprise risk management functionalities with 3D data capture, as well as flexibility of deployment – on the Cloud, as SaaS, or onsite.

Aveva offers modern industrial operations a complete modelling and management platform. Our solution is all-encompassing because anything short of that would not produce the desired outcomes in such a complex environment.

According to a 2017 study from McKinsey, 98 per cent of megaprojects incur cost overruns or delays. The average cost increase is 80 per cent of the original value, with an average slippage of 20 months from the original schedule. These are massive numbers and a lot of this boils down to how data-centric owner operators are today. Aveva addresses that gap by bringing together three major data sources to create a digital twin – a virtual representation of a physical asset – comprising that asset’s real-time data, engineering data and maintenance data.

The engineering data is a combination of 1D, 2D and 3D information – everything from datasheets to piping and instrumentation diagrams to laser scans. In this scenario, lists and datasheets are all aligned with 3D models and schematics, ensuring quality deliverables. You can avoid procurement errors and delays, as well as rework in construction. This can have a significant impact on a project’s total installed cost (TIC) with savings of 10 per cent. On a $1bn project, a $10m investment in Aveva software could provide a TIC saving of $100m.

Q. What are your predictions for regional digitisation in the mid-term?

Operating, engineering and maintaining assets optimally are the three pillars of asset performance management. Industries in the region are showing an enthusiasm for digitisation because it can help them reliably achieve these outcomes. Industry 4.0 has captured imaginations because of its possibilities, but technologies such as IoT, artificial intelligence and machine learning also require domain expertise and case specific innovations to be optimal. Over the mid-term, I see highly tailored, customer and project-specific digitisation becoming the norm in the region.

Another area with growth opportunities is the way industries organise knowledge management and approach knowledge capture and distribution to embrace a lean organisational approach and achieve true democratisation of knowledge.

You might also like...

Contractors begin Riyadh metro line two extension works

04 March 2026

Saudi Arabia’s private sector steps up

04 March 2026

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.

Take advantage of our introductory offers below for new subscribers and purchase your access today! If you are an existing client, please reach out to your account manager.