Despite running more than a year behind its proposed schedule, Saudi Arabia’s North-South Railway is being upheld as a new model for Middle East passenger and freight rail projects

With a planned 2,750 kilometres of track, the Saudi Railway Company (SAR) project (formerly known as the North-South Railway) linking mineral reserves and towns in northern Saudi Arabia with Riyadh and the Gulf coast is the world’s largest railway construction scheme.

About 75 per cent complete, it has already redefined what can be built in a demanding desert environment and is changing the way Saudi Arabia thinks about land transport.

The initial single-track phase of the SAR project started operating in May 2011, when the first load of phosphate mined at Al-Jalamid in northern Saudi Arabia completed the 1,800km journey to Ras al-Khair on the Gulf coast. Known as the mineral route, the first phase runs south from Al-Jalamid to Al-Jouf and proceeds from there south-east through Hail to the north of the kingdom’s Qassim province. The mineral route then heads north-east to pass through Az-Zubirah, the site of a bauxite mine that is due to open in 2014, and then directly east to Ras al-Khair on the Gulf. This section of the SAR project was due to be declared officially open this summer.

Airport link

The second phase calls for a line to run from the junction in north Qassim and head south-east through the central Najd to Sudair and finally to a station near King Khaled International airport (KKIA). This phase will mainly serve passengers. Work on the line is being completed and contracts for the stations have been placed. Operations will start in 2014.

Three further phases are now under way. Work has begun on designing a connection between Ras al-Khair and Jubail Industrial City about 60km to the south. This will connect with an 85km freight train network within the city that will take industrial products from Jubail’s heavy industries to Jubail Industrial Port for export. The Jubail network will be procured in a separate contract.

The third new phase involves building an extension from Jubail, 115km to the south, to Dammam, where the SAR project will connect with the existing freight and passenger railway lines from Riyadh.

This will not be the end of the SAR project, however. Plans are on the table to build a connection from KKIA around the outskirts of Riyadh to join the line to the city. This suggests the final length of the SAR project will be 3,000km, about the same as the distance between Bilbao in northern Spain and Moscow and the equivalent of travelling from Chicago to San Francisco.

The SAR Project’s progress is an inspiration for other railway schemes in the kingdom and region

The SAR project will connect cities and towns with a total population of up to 10 million, roughly a third of the Saudi total. It is by far the kingdom’s largest railway project, overshadowing the Damascus-Medina railway, which was completed in 1908, and the double Riyadh-Dammam railway (the first line was built in 1951 and is now used exclusively for freight; the second, for passengers only, was completed in 1982). In terms of cost and complexity, the SAR project can claim to be the kingdom’s most important transport initiative, rivalling the King Abdulaziz International Airport in Jeddah, gateway to the holy cities of Mecca and Medina.

The SAR project’s progress is an inspiration for other passenger and freight railway schemes in the kingdom and region. By providing a way that oil and goods could in future be exported from Eastern Arabia without passing through the Strait of Hormuz, it has global strategic significance. It is too soon to reach firm conclusions about all the lessons the SAR project can teach the region and the world, although some are already evident.

Royal approval for rail project

The SAR project will go down in history as probably the most important major scheme completed in the reign of King Abdullah, who succeeded his brother King Fahd in 2005. The line runs through Hail, the home town of King Abdullah’s mother’s family, and is designed to promote economic activity and employment in the heartlands of the Al-Saud clan. King Abdullah’s strong support for the SAR project has been essential and this is reflected in the fact that the project was developed by SAR, a government company owned by the Public Investment Fund (PIF). This is an agency of the Ministry of Finance.

Economic case for railway

The world is full of railway lines that do not make money or economic sense. Saudi Arabia had major railway plans in the pipeline for decades, but nothing came to fruition because the government did not have the money and backers saw no way of making a return on their investment. Roads are cheaper to build and run. So those sponsoring the SAR project had to make an economic case strong enough to overcome normal objections.

The most important influence on getting approval was the Saudi Arabian Mining Company (Maaden), the quoted joint firm that is the largest Arab minerals and mining business. Established by the Saudi government, Maaden inherited studies that identified commercial reserves of phosphates around Al-Jalamid and of bauxite at Az-Zubirah. These could only be profitably developed if a low-cost transport connection to export markets could be found.

But even if this made sense, why should Saudi Arabia invest in a railway system that would entail the kingdom exporting unprocessed raw materials? The next step was convincing the Saudi Basic Industries Corporation (Sabic), the Middle East’s most valuable quoted manufacturing firm, that it could benefit from developing Maaden’s reserves of phosphates and bauxite. For Sabic, that meant building world-class industries that would produce high-value-added products with strong export potential: phosphatic fertilisers and aluminium.

As the scale of the proposed downstream industry associated with the mineral development plans grew, it became clear that constructing a new industrial centre to accommodate it made sense. A site at Ras al-Zour, now named Ras al-Khair, was set aside for the exclusive use of minerals industries.

Validating Sabic’s investment in these industries, and particularly, for the first time, in aluminium, required getting low-cost energy and a serviced industrial site. Saudi Aramcoapproved energy supplies for the new industries. The Royal Commission for Jubail & Yanbu, which manages the Jubail and Yanbu industrial estates, came on board and was joined by the suppliers of key utilities: the Saudi Electricity Company and the Saline Water Conversion Corporation.

The final step was securing partners to provide technology and access to world markets. Alcoa is investing with Maaden in an integrated alumina refinery and aluminium smelter that will also have a world-scale rolling mill. Maaden separately set up the Maaden Phosphate Company in a 70:30 joint venture with Sabic, already an established nitrogenous fertiliser manufacturer. Its final capacity will be 3 million tonnes a year (t/y) of granular DAP fertiliser and 400,000 t/y of excess ammonia.

Although these projects demanded huge additional investment, their projected returns underpinned the SAR project’s economics. Plans have also been developed for a new industrial estate at Sudair on the passenger section of the railway. Earlier this year, Saudi Arabia’s Petroleum & Minerals Minister, Ali Naimi, announced the government would invest more than $1bn in a new mineral industries city near Turaif, which would be connected to the SAR project. Plans call for seven large factories processing phosphates for industrial and agricultural markets. It is estimated that Waad City will create about 25,000 jobs.

Saudi Arabia state finance

The SAR project had to be government financed and supported. Having the PIF develop the project instantly established its credibility and provided comfort to those considering working on the scheme. Sadara, the joint-venture company owned by Saudi Aramco and Dow Chemical that is developing a new integrated petrochemicals plant in Jubail, has agreed to support the Jubail Industrial City freight railway network.

Technical issues for rail project in Saudi Arabia

The SAR project involved addressing a host of construction challenges. The alignment required getting permission from land owners and the right of way through traditional camel-grazing and migration areas. To win them over, the SAR project provides an exceptional number of crossing tunnels for animals and herdsmen. The SAR project crosses more than 330km of sand-dune desert. This entailed establishing stable foundations for the line and clearing dunes for hundreds of metres on both sides. Workers and managers were accommodated in specially constructed camps. Raw materials were delivered by truck over long distances. More than 5 million concrete sleepers were manufactured in purpose-built factories.

Efficient operation

SAR decided to use the European Train Control System (ETCS) level 2 technology. It has acquired high-quality freight train and passenger train sets. The freight teams have been hired, but the big operational challenge will come in 2014 when passenger services start.

Running more than a year behind its original schedule, the SAR project is nevertheless regarded as a new model for Middle East passenger and freight railway projects. Confidence in the capacity of SAR to deliver has been reflected in the fact the company has been appointed to deliver the East-West Landbridge, which will connect Jeddah Islamic port with Riyadh.

| Key facts (phases one and two) | |

|---|---|

| Total final length | 2,750km |

| Length completed | 1,800km* |

| Number of bridges (planned) | 148 |

| Number of culverts (planned) | 2,900* |

| Quantity of earthwork | 509 million cubic metres |

| Number of concrete sleepers | 5 million |

| Estimated final cost | SR20bn |

| Length of extensions (Ras al-Khair-Jubail-Dammam) | 260km* |

| Estimated length of KKIA to Riyadh-Dammam line | 60km |

| *=Approximate; KKIA=King Khaled International airport. Source: MEED | |

The kingdom is banking on greater regional co-operation to deliver further value from its investment in the SAR project. SAR has expressed interest in building an extension from Al-Haditha to the Jordan Petroleum Refinery in Zarqa and for Jordan and Saudi Arabia to work together to develop an efficient freight link to the Syria border, though violence in Syria is making this look less attractive. Meanwhile, work is starting on freight and passenger lines in Oman, the UAE, Qatar and Kuwait as part of the GCC railway plan.

The SAR project’s full potential will only be realised when the regional railway network is fully developed. But that will not be for years and perhaps decades. For the moment, it must stand on its own two feet and SAR’s first goal is demonstrating that it can.

Main contracts for first two phases

- CTW 100 for the 555km stretch from Az-Zubirah to Ras al-Khair, which was won by the Saudi Binladin Group

- CTW 200 for the 454km stretch between Al-Zubara and Al-Jouf, awarded to a joint venture of Al-Suwaiket and the China Railway 18th Bureau

- CTW 300 for the 818km between Jouf and Al-Jalamid and for the link to Al-Haditha station close to the Jordan border. This was won by a joint venture of Laing O’Rourke and Mitsui and the local Al-Rashid Trading & Contracting Company

- CTW 400 for the 460km section from north Qassim to Riyadh, won by a joint venture of Al-Ayuni Investment & Contracting Company and Al-Omaier Trading & Contracting Company, both of Saudi Arabia, and China Civil Engineering & Construction Company

- The An Nafud 4.2-1 contract, won by Al-Omaier and Al-Fahad, for a section through the desert

- The 160km An Nafud 4.2-2 contract, won by the local Abdullah A M Al-Khodari Sons Company, also through the desert

- Contracts have also been placed for five of the six stations to be built on the passenger section, a main maintenance depot and 15 track maintenance centres.

You might also like...

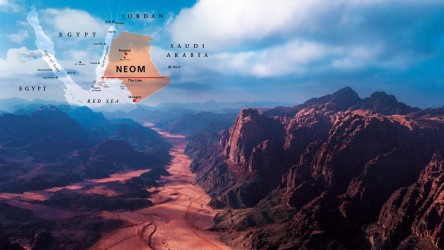

Neom seeks to raise funds in $1.3bn sukuk sale

19 April 2024

Saudi firm advances Neutral Zone real estate plans

19 April 2024

Algeria signs oil deal with Swedish company

19 April 2024

Masdar and Etihad plan pumped hydro project

19 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.