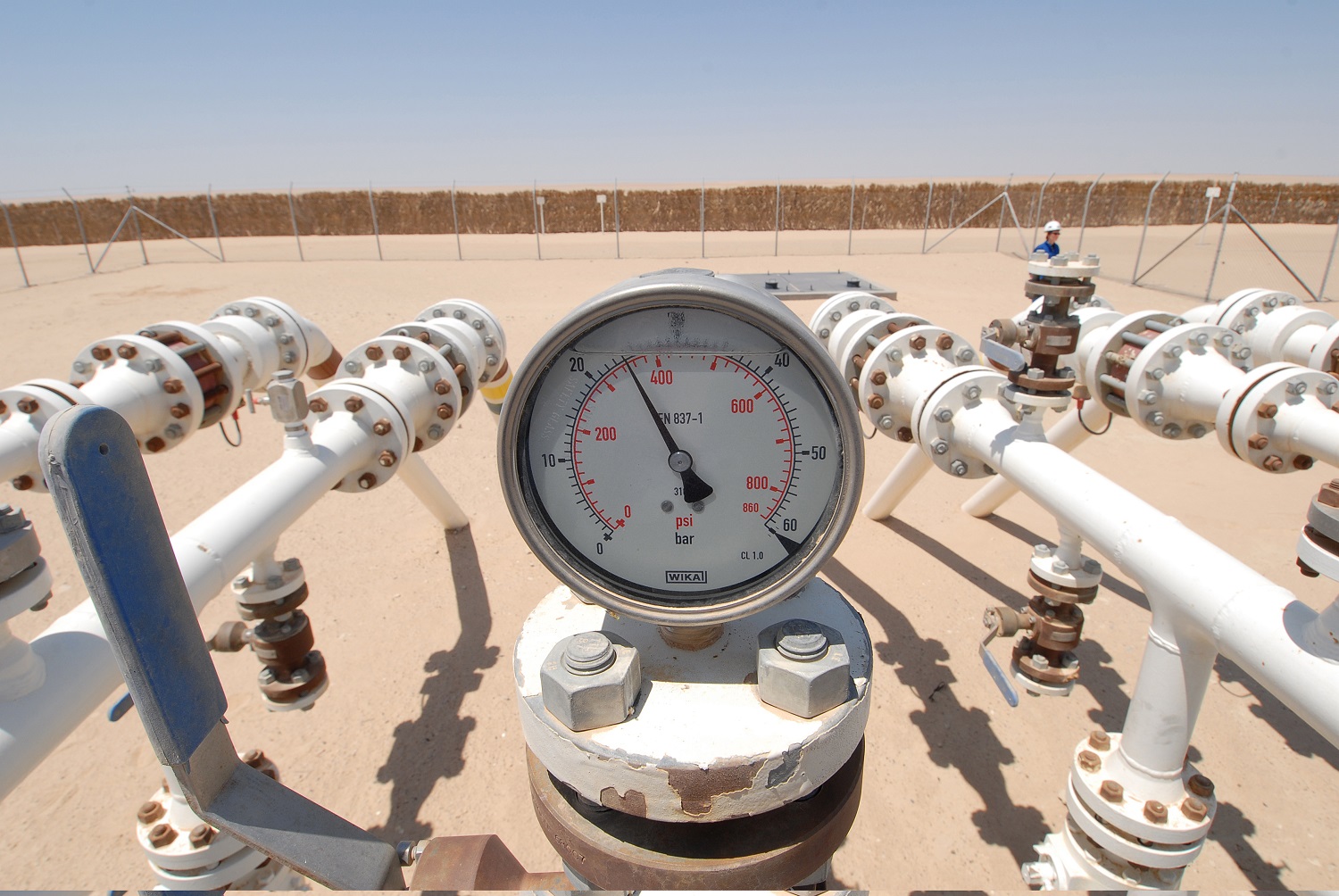

Saudi Arabia’s Ras al-Khair industrial city is a showcase of the kingdom’s plan to exploit its vast mineral reserves for economic diversification and job creation

Over the past two decades, Saudi Arabia’s Jubail and Yanbu industrial cities have developed into the world’s largest hubs for processing hydrocarbons, with several oil refineries and petrochemicals plants located alongside desalination and power facilities.

As well as hydrocarbons, minerals are abundant in the kingdom and over the past five years, Riyadh has initiated a series of measures aimed at developing world-scale operations that can fully exploit reserves of phosphates and bauxite. It has built an industrial city at Ras al-Khair in the Eastern Province, to further this goal.

The Saudi Arabian Mining Company (Maaden) was formed in 1997 with a remit to fully exploit the kingdom’s vast mineral reserves. Feasibility plans were initiated and after a series of studies, it was decided to develop downstream facilities for both phosphates and bauxite in the Eastern Province.

Minerals city in Saudi Arabia

In 2002-03, initial plans considered by Maaden included building a fertiliser complex to process phosphate in Jubail and an aluminium complex at Ras al-Zour. Both would be served by a railway that would transport minerals from mines in the north of the kingdom.

After a series of consultations with the government body responsible for industrial areas, the Saudi Arabian General Investment Authority (Sagia), it was decided in 2006 that the best option would be to develop a fully integrated minerals city with two major complexes and a number of smaller industrial parks built around it. In 2011, the name was changed from Ras al-Zour to Ras al-Khair by royal decree.

The development, also known as Mineral Industrial City, lies 60 kilometres north of Jubail and is being developed under the control of the Royal Commission of Jubail & Yanbu. When completed, it will be home to a major fertiliser complex, a fully integrated aluminium facility and a port. Maaden expects 27,000 jobs will be created at Ras al-Khair when all the planned projects are fully operational. The majority of the infrastructure is now in place, with most of the roads completed, as well as the railway and a major port.

The Saudi Ports Authority expects more than 4.3 million tonnes a year (t/y) of mineral derivative exports when Ras al-Khair’s two major projects are fully operational. However, this figure does not include any exports of downstream aluminium products. The authority also anticipates imports to reach 660,000 t/y.

Power and desalinated water will be supplied by the local Saline Water Conversion Corporation (SWCC). A combined-cycle power plant is being constructed with a capacity of 2,800MW. A water desalination plant is also under execution. When completed it will provide 228 million gallons a day (g/d) of water using multi-stage technology and 68 million g/d using reverse osmosis.

The North-South minerals railway, linking bauxite and phosphate mines at Al-Jalamid in the north of the kingdom to the industrial complex at Ras al-Khair, is already operational. Saudi Arabian Railway is planning to extend the line to Jubail and Dammam further south.

The line commenced operations in May 2011 and transports 5 million t/y of phosphates to Ras al-Khair from Al-Jalamid. The line is a vital aspect of Mineral Industrial City and started operations a month before the fertiliser plant at Ras al-Khair began its commissioning phase.

Saudi Arabia phosphate output

The $5bn fertiliser complex is a 70:30 joint venture between Maaden and Saudi Basic Industries Corporation (Sabic). The complex processes the phosphates from Al-Jalamid and includes a phosphoric acid plant, a sulphuric acid plant, an ammonia plant, a diammonium phosphate fertiliser (DAP) granulation plant and a co-generation and desalination plant, as well as other facilities.

When fully commissioned, the complex will produce 3 million t/y of DAP, which represents about 10 per cent of current global demand. Sabic will market 77 per cent of the offtake, with Maaden selling the remainder.

Commercial production commenced on 1 February and the offtake from the plant will be sold on the international market, with 400,000 t/y of surplus ammonia being sold domestically. The complex can also produce monoammonium phosphate if market requirements demand it.

The fertiliser complex was the first mega-project executed by Maaden and cemented the kingdom’s place as a global player in the phosphates derivatives sector.

“The scope of this project, when you look at how it utilises the full value chain of the kingdom’s phosphates resources, is very impressive,” said Yahya S al-Yami, vice-president for phosphate & industrial minerals at Maaden, on the sidelines of the Saudi Downstream 2012 conference in Jubail in March.

“We have been patient and have taken many diverse factors into consideration, but the end result justifies this.”

The scale of Maaden’s phosphates joint venture operations is impressive, but the vast majority of its offtake will be sold and offers little in the way of further downstream development. However, plans for its bauxite reserves are being designed to add value and create thousands of direct and indirect employment opportunities in the area.

The $10.8bn aluminium complex is currently under construction by Maaden and its joint venture partner, the US’ Alcoa. The complex will act as an anchor for what Riyadh hopes will be scores of small conversion industries that can add further value to the aluminium that will be produced from the kingdom’s bauxite reserves.

Aluminium production in Saudi Arabia

Four million t/y of bauxite will be transported from Maaden’s mines at Al-Baitha and will feed into a 1.8 million t/y alumina refinery. This will in turn supply an aluminium smelter that will produce 740,000 t/y of primary metal. Part of the offtake from the smelter will be sold by Alcoa on the international market, but the remainder will provide the feedstock for several downstream aluminium industries.

| GCC aluminium smelting capacity | ||

|---|---|---|

| Scheme | Location | Capacity (tonnes a year) |

| Dubai Aluminium | UAE | 920,000 |

| Emirates Aluminium | UAE | 750,000 |

| Qatar Aluminium | Qatar | 585,000 |

| Bahrain Aluminium | Bahrain | 870,000 |

| Sohar Aluminium | Oman | 350,000 |

| Maaden/Alcoa | Saudi Arabia | 750,000 |

| Source: MEED | ||

The centrepiece of the downstream facilities will be a 380,000-t/y rolling mill, which is currently being constructed by South Korea’s Samsung Engineering using technology provided by Germany’s SMS Group. The rolling mill is the largest to be built outside China in the past 20 years and will provide aluminium sheet to food packaging manufacturers across the kingdom and the rest of the GCC.

“This has always been a massive project and there has never been any doubt in our minds that Riyadh plans to showcase both the aluminium complex and Ras al-Khair as the kind of industrial diversity it is capable of,” says an executive from one of the major contractors working on the scheme. “There are several stakeholders involved due to the sheer scale of the project, but it is clear to everyone that the construction phase and subsequent start-up needs to be a success. There is a lot riding on it.”

The smelter and rolling mill will commence operations in 2013, with the mine and alumina refinery coming online a year later. With the complex being at such an advanced stage, both Maaden and Alcoa are already starting to commission further downstream developments at Ras al-Khair.

In March, the joint venture partners awarded the US’ Fluor a $250m contract to build a 100,000-t/y automotive sheet plant. The facility will produce aluminium panels for use in vehicle manufacturing. The move is the first major step aimed at setting up an automotive manufacturing sector in the kingdom.

The offtake can be used by the component providers, including manufacturers of engine blocks, wheels and forged products. Other uses include supplying related sectors, such as manufacturing of trailers for commercial vehicles from lightweight aluminium.

One of the main reasons Ras al-Khair could prove attractive to investors is the relatively low cost of building a conversion plant that uses aluminium as its feedstock.

Speaking at a conference earlier this year, Khalid al-Luhaidan, director of planning, strategy and business development for Maaden, laid out the costs for any investors interested in building a conversion plant in the city.

Initial capital expenditure of $100m-150m would enable the construction of a 50,000 t/y plant that could produce automotive parts or aluminium foil and sheeting. Maaden and Sabic have confirmed they will offer potential investors full technical support and it is believed that preferential rates for rent and utilities will be offered, as well as a loan from the Saudi Industrial Development Fund.

Start-up worries

Several economic cities in the kingdom apart from Yanbu and Jubail have suffered from a lack of potential investors in their initial start-up periods and this will also be a cause of concern for Maaden.

However, due to the minerals the city has been designed to process, Maaden can afford to be patient and look to attract the right kind of investment from suitable companies that will complement its operations.

The executive from the major contractor says the city is in a unique position due to Maaden forming partnerships with the right firms and effectively insuring itself against any future issues.

“Most of the fertiliser is sold to Sabic’s customers, and if it came down to it Alcoa could find buyers for the whole of the smelter’s offtake,” he says. “This gives Maaden an opportunity to evolve the city without losing huge amounts of money waiting for companies to come to Ras al-Khair.”

Key fact

Maaden expects 27,000 jobs will be created at Ras al-Khair when all the planned projects are completed

Source: MEED

You might also like...

Red Sea Global awards Marina hotel infrastructure

18 April 2024

Aramco allows more time for MGS package revised prices

18 April 2024

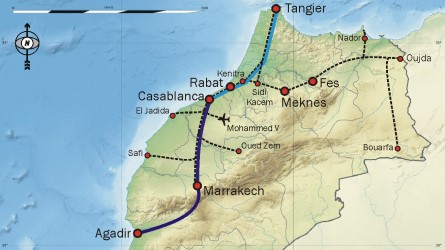

Morocco tenders high-speed rail project

18 April 2024

A MEED Subscription...

Subscribe or upgrade your current MEED.com package to support your strategic planning with the MENA region’s best source of business information. Proceed to our online shop below to find out more about the features in each package.